3D visual inspection technology has played an important role in the battery industry, especially in the production of power batteries, helping to improve product quality and production efficiency. Compared to traditional 2D visual inspection, 3D vision can obtain three-dimensional geometric information of objects, thereby more accurately identifying and locating various subtle features and defects of batteries.

Today, we will introduce the application case of Yishi Technology's 3D line laser camera in battery testing!

Power battery testing

requirement analysis

·Material: Metal parts

·Dimensions: 25mm wide, 43mm high

·Color: Bright Silver

Testing requirements

·Pits and scratches on the polar cylinder surface

Camera selection

In response to the above detection requirements, Yishi Technology's LVM2020 line laser 3D camera is capable of performing this task. LVM2020 is a cost-effective 3D intelligent sensor; Can provide a full frame acquisition rate of 340Hz, with 2048 physical contour points and a maximum of 4096 depth map uniformly spaced sampling points; LVM2020 with precision to 0.3 μ The Z-direction repeatability accuracy of m provides the best target visibility with a near field of view (FOV) of 27.5mm and a far field of view (FOV) of 33.5mm, which can meet the needs of various scene detection applications.

Detection environment and installation method

·After the camera is fixed, the product moves in a straight line along the center for scanning and measurement;

·The testing platform needs to have stable encoder signal output;

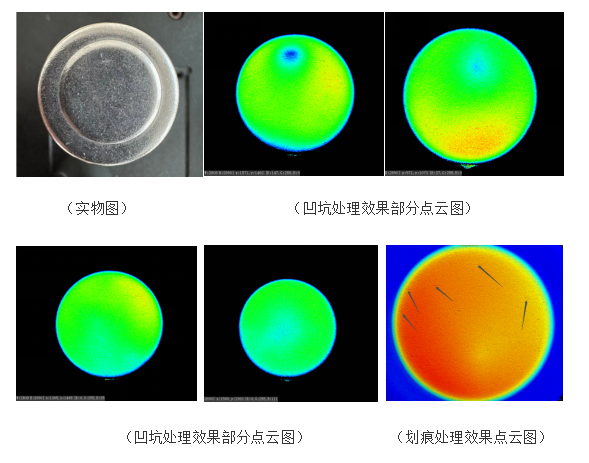

Sampling effect

Testing conclusion

·Yishi Technology's LVM2020 line laser 3D camera can detect defects such as dents and scratches on the pole surface of power batteries.

·Testing value: Supports high-speed continuous online testing without the need for manual intervention, greatly reducing the testing cycle, improving the operational efficiency and production capacity of the production line, while reducing labor costs and minimizing misjudgments and missed detections caused by human factors.

Yishi Technology was established in 2017 and is a high-tech enterprise that integrates industrial visual product design, research and development, production, sales, and service. The company focuses on the development of underlying algorithms and hardware implementation for industrial visual products, with a complete set of independent intellectual property rights in software and hardware technology, aiming to become the most trustworthy leader in visual sensors.

The LVM series 3D intelligent sensors developed by Yishi harden industry-leading 3D imaging algorithms into chips, achieving high-speed and high-performance measurements with a repeatability accuracy of 0.1 micrometers. The product's performance indicators exceed those of foreign peers and can be replaced by imports. At present, the company's products have been widely used in various fields such as consumer electronics manufacturing, new energy manufacturing, automotive manufacturing, sheet metal processing, wood processing, food and beverage processing, etc.

2024/03/12

2024/03/12