The safety and matching degree of automotive components play a crucial role in the entire vehicle manufacturing process. Improper component combinations may lead to safety issues such as power loss, increased vibration, and increased noise. Nowadays, 3D line laser cameras can achieve real-time quality monitoring and rapid feedback through more comprehensive, accurate, and efficient detection, further improving the efficiency and quality of the entire production process, and meeting the industrial production needs of modern automobiles.

Today, we will introduce the application case of Yishi Technology's 3D line laser camera in automotive component inspection!

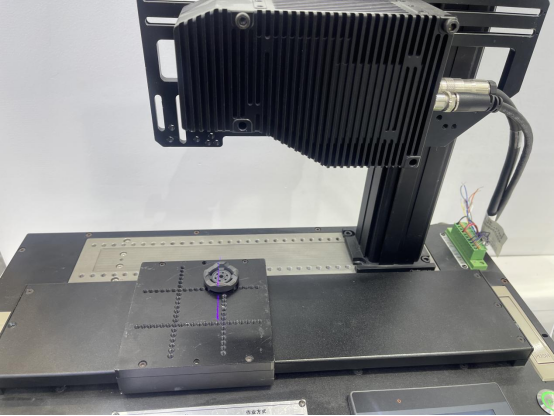

Precision equipment workpiece inspection

Requirement Analysis

·Material: Metal parts

·Size: Irregular shape with a diameter of 3cm

·Color: Black

Testing requirements

·Workpiece size, shape, and surface defects

Camera selection

In response to the above detection requirements, Yishi Technology's LVM2330 line laser 3D camera is capable of performing this task. LVM2330 is designed specifically to meet the harsh production environment of factories and is suitable for scenarios of fast moving object detection; Can provide a full frame acquisition rate of 1000Hz, with 1920 physical contour points and a maximum of 4096 uniformly spaced depth map sampling points; LVM2330 accurate to 0.6 μ The Z-direction repeatability accuracy of m provides the best target visibility with a near-end field of view (FOV) of 55.4mm and a far-field field of view (FOV) of 90.5mm, which can meet the needs of various high-speed and large-scale detection applications.

Detection environment and installation method

·After the camera is fixed, the product moves in a straight line along the center for scanning and measurement;

·The testing platform needs to have stable encoder signal output;

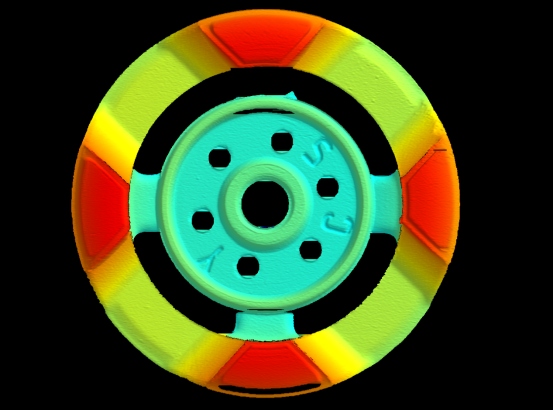

Image collection effect

(Point Cloud Map)

Testing Conclusion

·Yishi Technology's LVM2330 line laser 3D camera can detect the size, shape, and surface defects of precision automotive workpieces.

·Testing value: Ensure minimal errors in the design and manufacturing process, efficiently and stably identify workpiece defects, and ensure the reliability of automotive component assembly.

Detection of line contour and positional accuracy of water-cooled plate components

Requirement Analysis

Material: Metal parts

Size: 215mm x 185mm

Color: White

Testing requirements

·By detecting whether there are local protrusions or dents on the outer edge of the contour

·Position detection, testing whether each area on the material is within the specified position deviation of the material

Camera Selection

In response to the above detection requirements, Yishi Technology's LVM2040 line laser 3D camera is capable of performing this task. LVM2040 is a cost-effective 3D intelligent sensor; Can provide a full frame acquisition rate of 340Hz, with 2048 physical contour points and a maximum of 4096 uniformly spaced depth map sampling points; LVM2040 with precision to 1.2 μ The Z-direction repeatability accuracy of m provides the best target visibility with a near-end field of view (FOV) of 110.7mm and a far-field field of view (FOV) of 233.9mm, which can meet various scene requirements.

Detection environment and installation method

·After the camera is fixed, the product moves in a straight line along the center for scanning and measurement;

·The testing platform needs to have stable encoder signal output;

·The camera has an adjustable shooting distance of 260mm ± 5mm

Image collection effect

Testing conclusion

·Yishi Technology's LVM2040 line laser 3D camera can detect the contour and positional accuracy of the water-cooled plate components

·Detection value: Through real-time and high-precision 3D visual inspection, we achieve fully automatic detection for customers, improve product quality, and reduce costs and increase efficiency.

Yishi Technology was established in 2017 and is a high-tech enterprise that integrates industrial visual product design, research and development, production, sales, and service. The company focuses on the development of underlying algorithms and hardware implementation for industrial visual products, with a complete set of independent intellectual property rights in software and hardware technology, aiming to become the most trustworthy leader in visual sensors.

The LVM series 3D intelligent sensors developed by Yishi harden industry-leading 3D imaging algorithms into chips, achieving high-speed and high-performance measurements with a repeatability accuracy of 0.1 micrometers. The product's performance indicators exceed those of foreign peers and can be replaced by imports. At present, the company's products have been widely used in various fields such as consumer electronics manufacturing, new energy manufacturing, automotive manufacturing, sheet metal processing, wood processing, food and beverage processing, etc.

2023/12/01

2023/12/01