SenseTime AI Industrial Solutions Partner Conference and New Energy Lithium Battery Testing Product Solution Conference

On January 7, Yishi Technology was invited to attend the SenseTime AI Industrial Solutions Partner Conference and the New Energy Lithium Battery Testing Product Solution Conference, and participated in the awarding ceremony of ecological partners.

About SenseTime

As an artificial intelligence software company, SenseTime has deep academic accumulation and long-term investment in original technology research, continuously enhancing industry-leading full-stack artificial intelligence capabilities, covering perception intelligence, decision intelligence, intelligent content generation and intelligent content enhancement, etc. Key technical fields include key capabilities including AI chips, AI sensors, and AI computing infrastructure.

SenseTime's business covers four major sectors: smart business, smart city, smart life, and smart car. The related products and solutions are well received by customers and partners.

Yishi Technology - SenseTime Industrial Ecological Partner

Yishi Technology is honored to be the industrial ecological partner of SenseTime. In the new year, in the face of a new journey, Yishi Technology will continue to walk hand in hand with SenseTime and make progress together!

Application of Nextvision 3D camera in new energy manufacturing industry

With the rapid development of the new energy vehicle industry, the new energy vehicle manufacturing process has attracted great attention. Two very important modules are involved in the new energy vehicle manufacturing process: thermal management module and power battery module.

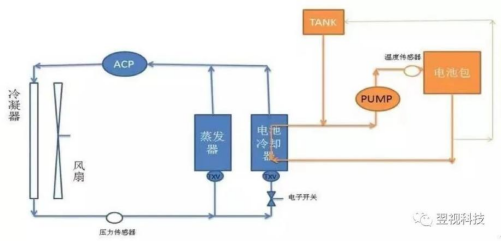

01Battery thermal management system

The battery thermal management system (BTMS) is the main function of the battery management system. The thermal management of the battery mainly includes functions such as cooling, heating and temperature equalization. The cooling and heating functions are mainly adjusted according to the possible influence of the external ambient temperature on the battery. Temperature equalization is used to reduce the temperature difference inside the battery pack and prevent rapid decay caused by overheating of a certain part of the battery. The closed-loop regulation system is formed by the heat transfer medium, the measurement and control unit and the temperature control equipment, so that the power battery can work within a suitable temperature range to maintain its optimal state of use to ensure the performance and life of the battery system.

Aiming at the detection requirements of battery thermal management systems in the new energy vehicle manufacturing industry, such as cooling plate flatness and height difference detection, fin height detection, heat exchange pressure detection, thermal valve seat concentricity detection, etc. All are supported, and there are rich application cases. Especially for large-format, high-precision detection scenarios, Nextvision Technology provides a complete multi-camera splicing solution to assist integrators partners to quickly implement projects.

Nextvision Technology Case 1

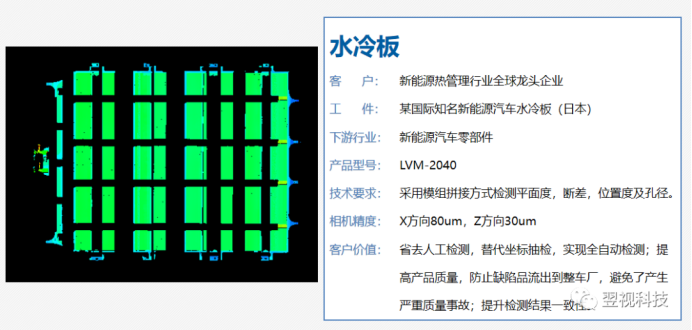

Cooling plate flatness and height difference detection:

needs and solutions

■Measurement object: detection of water-cooled plate flatness, height difference, position, etc.;

■Accuracy requirements: Z±0.05MM, XY0.08MM;

■Beat requirements: The product is scanned within 5S (the product is 1200MM wide and 1400MM wide) with a design speed of 240MM/S, and the required 3K FPS. The LVM-2040 camera can reach a maximum of 10K FPS, which meets the rhythm requirements;

■Measurement plan: 10 LVM-2040 camera array scans, set reasonable thresholds for flatness, difference and position through the NVT_PRO image algorithm platform, within the threshold range OK, beyond the threshold NG;

■Mechanism: high-precision servo motion control;

■Technical highlights: 1. The LVM-2040 camera uses the self-developed array mode, and there is no need to contact the source of each camera; 2. The phase clock mode can avoid the interference of the laser lines of each camera;

■Conclusion: The NextVision camera LVM-2040 can be easily and quickly deployed in large-format multi-camera projects.

Vision Technology Case 2

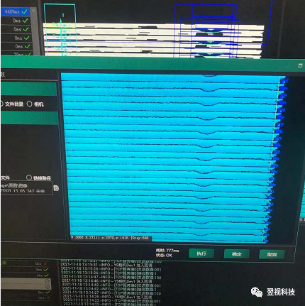

Fin height detection:

needs and solutions

■Measurement object: heat exchanger in automobile air conditioner;

■Accuracy requirements: detect the number of laminations of each product, the order of laminations, and whether the lamination distance is OK;

■Beat requirements: The product is scanned within 2S (the product is 120MM in length and 130MM in width), and the design speed is 70MM/S, and the required 3K FPS, the LVM-2040 camera can reach up to 10K FPS, which meets the rhythm requirements;

■Measurement plan: 1 LVM-2040 camera scans, adjusts the image to the ideal detection state through the LVM_CAPUTURE image algorithm platform, and uses the corresponding operator to detect the number, order and distance;

■Mechanism: high-precision servo motion control;

■Technical highlights: The internal parameters of the camera can be adjusted to avoid the interference caused by some reflections on the surface of the product, and the detection can be set by increasing the number of camera lines according to different product specifications.

02Power battery

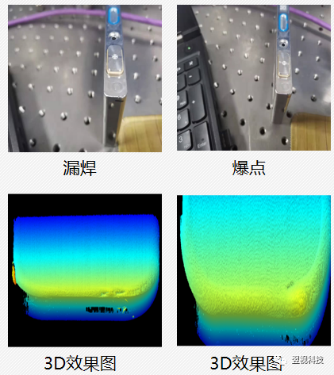

For the production process of power battery cells in the new energy manufacturing industry, Yishi Technology provides a complete set of 3D inspection-based machine vision inspection solutions, covering the processing and inspection of square aluminum shells in the power battery cell process section (covering burst points, broken welding, Defect types such as bumps, concave welding, pinholes, offsets, cracks, flanging, etc.), welding quality inspection of cell sealing nails, and surface defect inspection of cell shells.

Nextvision Technology Case 1

High-speed inspection of the side welds of the battery cell shell of the power battery cell production line :

Cell production has the characteristics of high-speed online high-precision detection, which requires the camera to meet the high-speed point cloud data acquisition and processing of more than 10K frames per second point cloud outline. The LVM-2600 series launched by Nextvision Technology has high-speed acquisition performance of up to 56K point cloud contours per second, especially its innovative implementation of 10 Gigabit Ethernet data transmission and processing in the industry, which can transmit original point cloud data at high speed.

needs and solutions

■Measurement object: side weld defect of square aluminum shell battery;

■Accuracy requirements: +/- 0.1 MM, camera X/Z resolution within 20UM;

■Beat requirements: CT<4S, the camera can complete the measurement at a frame rate of more than 10K FPS;

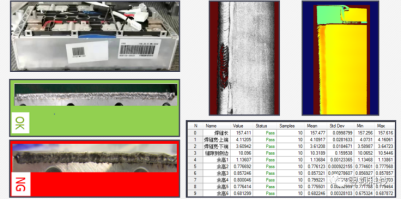

■Measurement plan: 3D inspection, use LVM-2620 camera to inspect the battery shell weld, use NVT-Proc image algorithm platform for side weld defect inspection (including false welding, explosion point, bump judgment algorithm), no defect judgment occurs OK, otherwise it is judged as NG;

■Mechanism: high-speed precision linear motion platform (high-precision servo control);

■Conclusion: Nextvision's LVM-2620 camera can meet the needs of cell shell welding inspection, and can fully meet the scanning speed of more than 10K under the premise of ensuring the image effect and detection accuracy.

Vision Technology Case 2

The on-line inspection process of power battery module production in the new energy manufacturing industry mainly includes post-weld inspection of power batteries, full-scale measurement of modules, flatness and positive and negative inspection of cylindrical cells. Nextvision Technology can provide a complete set of 3D inspection-based machine vision defect detection and multi-sensor data fusion full-scale measurement solutions. High-speed weld detection in module assembly production includes detection of virtual welding, explosion points, pinholes, pits, etc.

The LVM-2600 series uses a customized optical design to scan the side welds of highly reflective modules.

needs and solutions

■Measurement object: battery module weld defects;

■Accuracy requirements: +/- 0.1 MM, camera X/Z resolution within 20UM;

■Beat requirements: CT<4S, after calculation, it is required to complete the measurement at 10K FPS or more;

■Measurement plan: 3D inspection, use LVM-2620 camera to detect the side welds of the module, and use the NVT-Proc image algorithm platform for defect detection (including judging algorithms such as virtual welding, explosion points, bumps, etc.), if no defects are found, it is judged as OK , otherwise it is judged as NG;

■Mechanism: high-speed precision linear motion platform (high-precision servo control);

■Conclusion: Nextvision's LVM-2620 camera can meet the needs of side weld inspection. On the premise of ensuring image effect and inspection accuracy, it can fully meet the scanning speed of more than 10K.

Nextview Technology Case 3

Full-scale inspection of new energy power battery modules:

The production of battery modules has the characteristics of high-speed online high-precision detection, which requires the camera to meet the high-speed point cloud data acquisition and processing of more than 10K frames per second of point cloud contours. The LVM-2000 and LVM-2600 series launched by Nextvision Technology have high-speed acquisition performance of up to 56K point cloud contours per second, especially its innovative implementation of 10 Gigabit Ethernet data transmission and processing in the industry, capable of high-speed transmission of raw point cloud data .

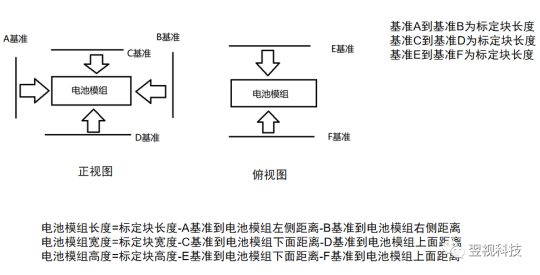

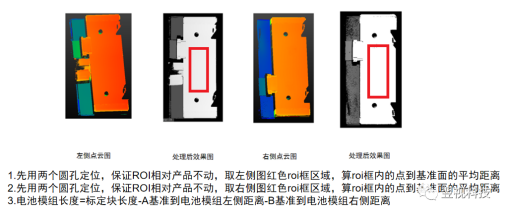

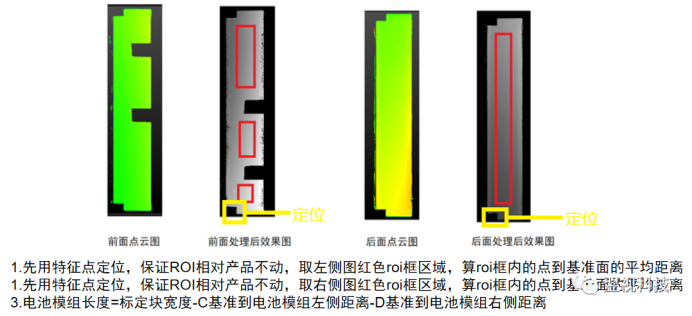

principle:

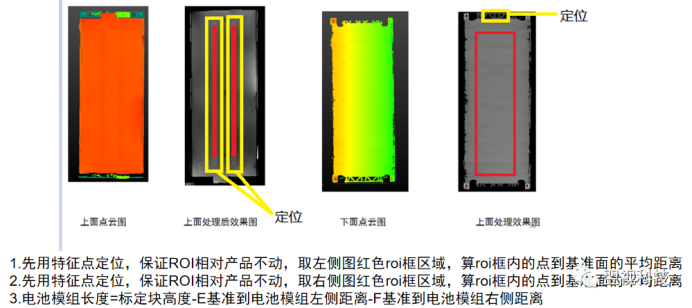

The total length of the module:

Overall width of the module:

The total height of the module:

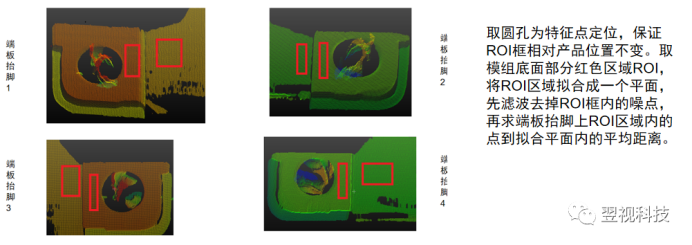

Lifting foot height of end plate:

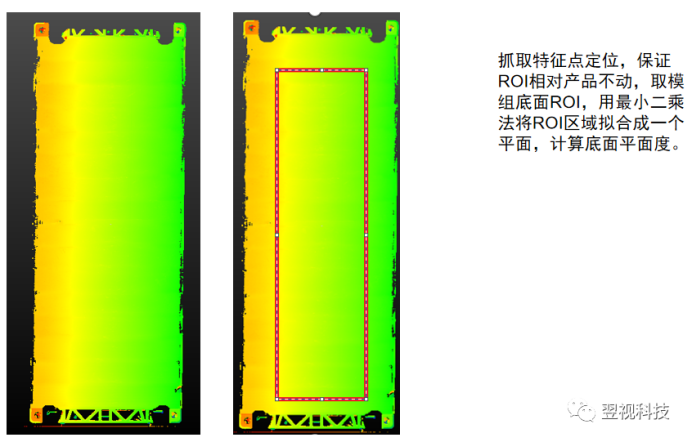

Bottom Flatness:

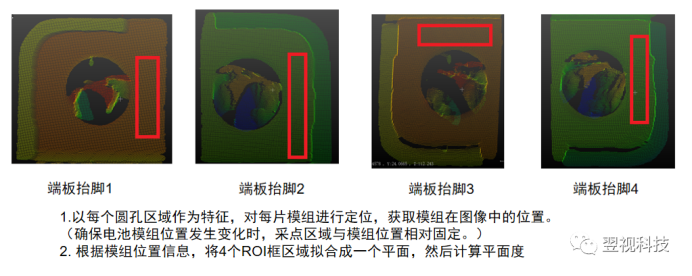

Flatness of the four corners of the end plate:

needs and solutions

■Measurement object: six-sided dimension detection of battery module;

■Accuracy requirements: ≥±0.3MM, camera X/Z resolution within 20UM;

■Beat requirements: CT<45S, the camera can complete the measurement at a frame rate of more than 10K FPS;

Measurement solution: 3D inspection, both ends and both sides of the module are detected by the LVM-2040 camera to detect the length, width and feature size of the battery, and the LVM-2645 camera is used to detect the module height and the height direction of the end plate. Use NVT-Proc Image algorithm platform, if there is no defect, it is judged as OK, otherwise it is judged as NG;

■Mechanism: high-speed precision linear motion platform (high-precision servo control)

■Camera features: It has the ability to capture images with large width and high speed;

■Conclusion: Nextvision's LVM-2040 and LVM-2645 cameras (with the 2D camera to complete the diameter and position detection of the end plate hole/electrode hole) can meet the six-sided size detection requirements of battery modules, and ensure the image effect and detection. Under the premise of accuracy, it can fully meet the scanning speed of more than 10K.

At present, Yishi Technology is the domestic 3D camera brand with the largest shipment in the new energy industry. It has very rich applications from water-cooled version detection to power battery detection to power battery component (top cover) detection. In addition, Yishi Technology has launched a variety of models to meet the needs of different industries. For more details, please contact us.

2022/01/07

2022/01/07