1. Background knowledge

In the production and assembly process of laptop computers, there are many parts that need to be assembled . The traditional method for defect detection of laptop battery compartments is manual measurement and judgment, but this method is easily affected by human factors such as subjective wishes, emotions, and visual fatigue of the inspectors. , so that there are deviations and omissions in the detection results. Therefore, the use of machine vision to replace the artificial naked eye and the installation of "eye-catching eyes" for the assembly of the assembly line have become an inevitable choice for enterprises.

2. Laptop battery compartment detection scheme

The all-in-one 3D industrial camera (LVM-2 030 ) of Nextvision Technology cooperates with the detection system software, which can detect foreign objects in the battery compartment, scattered screws, release paper, etc., and efficiently and accurately detect foreign objects. .

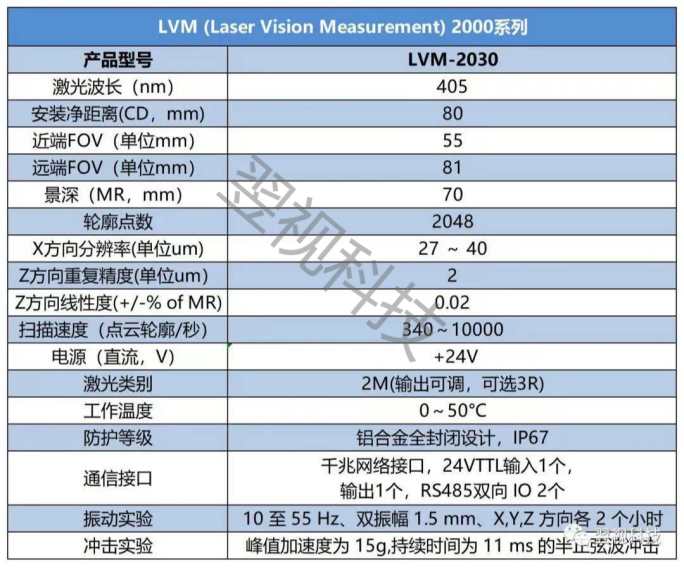

2.1 Adopt camera

All-in-one 3D line laser camera LVM-2 030 .

The LVM-2 030 has 2048 actual physical contour points in the X direction . The acquisition speed under full-frame is 340 frames per second , with a wide field of view of up to 80mm, and the Z-direction depth of field is greater than 70mm, which is suitable for foreign matter measurement inside the laptop battery compartment .

(LVM-2 030 parameter)

2.2 Detection method

It is beneficial to 3D point cloud data to detect whether there are foreign objects in the battery compartment : scattered screws , release paper, etc.

2.3 Detection effect

The true resolution of X direction can reach below 40um;

The repeatability of the testing equipment is within ±2μm;

·High-speed detection, the frame rate can reach 340fps in full frame.

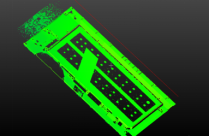

The detection and sampling effect is as follows:

Material point cloud

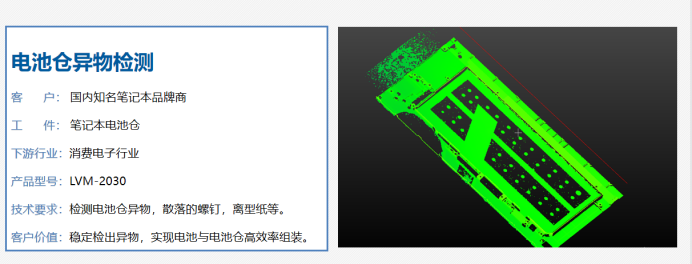

3. Application case

of flatness , breakage , scattered screws and release paper in the laptop battery compartment :

needs and solutions

■Measurement objects: detection of flatness , breakage , scattered screws and release paper in the battery compartment of the laptop ;

■Technical requirements: Z±0.05MM, FOV: 75MM;

■Beat requirements: Scan the product within 5S, (the product length is 200MM), the frame rate is about 3K, the LVM-2030 camera can reach up to 10K FPS, which meets the rhythm requirements;

■Measurement plan: A single LVM-2030 camera scans in the Y direction. After obtaining the point cloud image, the flatness and scattered screws are set to a reasonable threshold through the Capture image algorithm platform. The threshold is OK, and the threshold is NG;

■Mechanism: high-precision servo motion control;

■Technical highlights: Before the battery is assembled, the LVM-2030 camera checks the flatness of the battery compartment, scattered screws, release paper, etc. to ensure the stability of the battery installation.

■Customer value: Added automatic testing equipment to improve product quality control and increase end customer satisfaction.

about us About us

Founded in 2017, Yishi Technology Co., Ltd. is a high-tech enterprise integrating 3D machine vision product design, research and development, production, sales and service. Yishi Technology is located in Ningbo (operation headquarters) and Shanghai (R&D center), and has set up sales and technical support centers in East China (Suzhou) and South China (Shenzhen). The company's core team brings together doctors from famous universities, executives from famous enterprises and technical cores. Focusing on the research and development of machine vision products, the development of underlying algorithms and hardware implementation, it has a full set of software and hardware technologies with independent intellectual property rights, and is committed to becoming a world-class visual sensor company. The precision and performance of the company's high-end products have already surpassed those of the same foreign products, enabling import substitution. The company's products have been widely used in consumer electronics manufacturing, new energy manufacturing, automobile manufacturing, sheet metal processing and other fields. In a wide range of landing applications, it saves customers more than half of the cost on average, and is highly praised.

contact us Contact us

headquarters

15th Floor, Building 1, Tsinghua Science and Technology Park, No. 119 Zicheng Road, Yinzhou District, Ningbo City

R & D Center

Room B2, 8th Floor, Block B, Kehai Building, No. 800 Naxian Road, Zhangjiang Science City, Pudong New Area, Shanghai

Subsidiary

Room 1705-1706, 17th Floor, East Building, Building A, Fanhua Center, Xiangcheng District, Suzhou

Shenzhen Office

Room 1001, 10th Floor, Yonghui International Business Building, Baoan District, Shenzhen

contact number:

0574-55337778

Company official website:

www.nextvision-tech.com

Company email:

info@nextvision-tech.com

2022/03/08

2022/03/08