1. background knowledge

The 3C industry includes a general term for computers, communications, and consumer electronics. Among them, computers mainly refer to computers, which can be subdivided into desktop computers, notebook computers and tablet computers; communication products include mobile phones and walkie-talkies; there are many types of consumer electronics, such as digital cameras, audio-visual entertainment equipment, etc. As a major manufacturing country, China has concentrated 70% of the world's 3C product production capacity, and the 3C electronics industry is one of the most important pillar industries.

At present, the competition in the mobile phone industry is very fierce, and the industry calls for higher-quality products, as well as more efficient and lower-cost processing and manufacturing technologies. The introduction of machine vision technology is bound to become a key measure for equipment manufacturers and manufacturing companies to reduce costs.

Today, I will introduce to you the application case of Nextvision LVM-2600 series cameras in the mobile phone manufacturing industry!

2. Mobile phone middle frame break detection

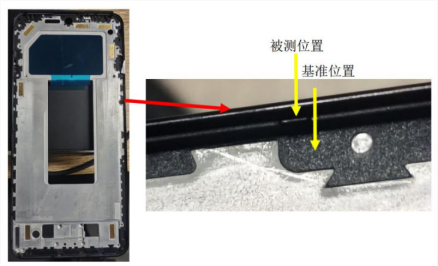

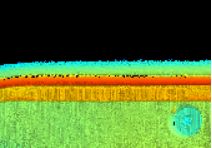

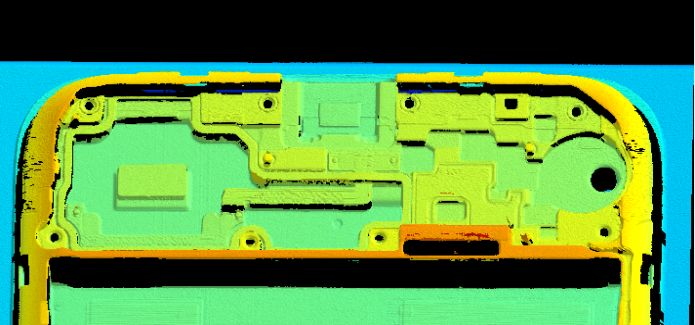

(Partial picture of the product in the middle frame of the mobile phone)

2.1 Demand Analysis

Detection object: mobile phone middle frame break

Detection accuracy: 0.01mm

Detection efficiency: 150 mm/ s on one side

2.2 Using the camera

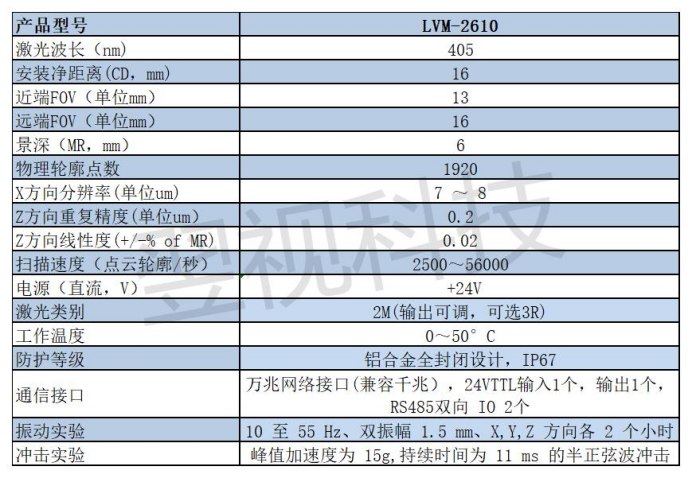

Integrated 3D Line Laser Camera LVM-2610

The LVM-2610 has 1920 actual physical contour points in the X direction. The acquisition speed of the full frame is 2500 frames per second, and the maximum can reach 56000 frames per second, which is suitable for high-precision detection.

(LVM-2610 series camera parameters)

2.3 Detection method

·The height from camera to product is 18mm .

·The camera is fixed and the middle frame of the mobile phone is detected along a straight line on the mobile platform.

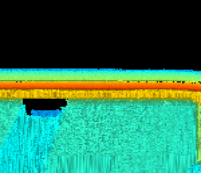

(Measurement location map)

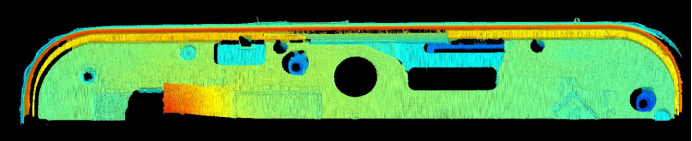

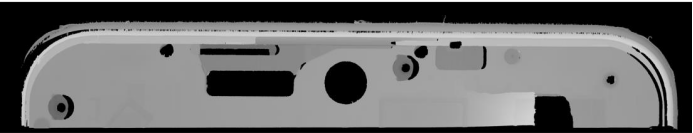

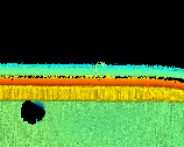

2.4 The effect of detecting and capturing images on the middle frame of the mobile phone

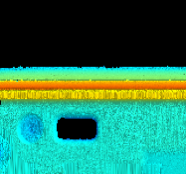

(point cloud map)

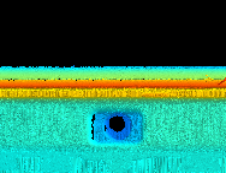

(depth map)

Measurement point on the upper edge of the middle frame

difference one difference two difference three

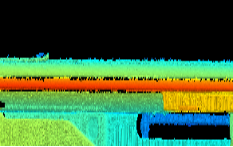

2.5 The effect of detection and acquisition under the middle frame of the mobile phone

(point cloud map)

(depth map)

The measurement point of the lower edge of the middle frame

difference one difference two difference three

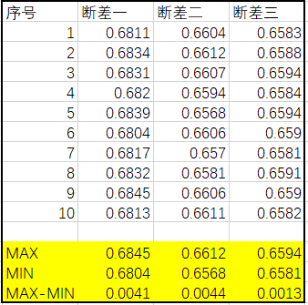

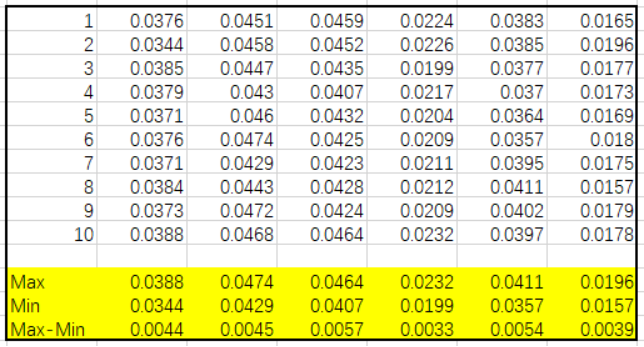

2.6 Test Results

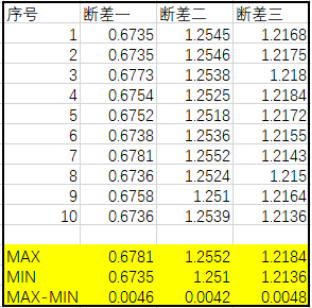

(Repeatability test data at the top of the middle frame of the mobile phone) (Repeatability test data at the bottom of the middle frame of the mobile phone)

3. Mobile phone screw hole height detection

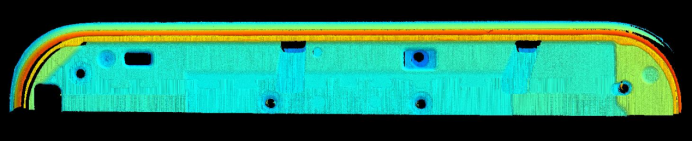

(Physical map)

3.1 Demand Analysis

Detection object: height detection of screw holes inside mobile phones

3.2 Using the camera

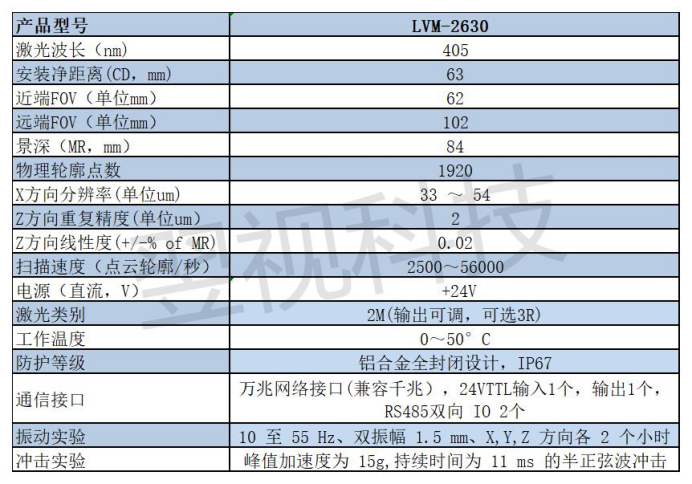

Integrated 3D Line Laser Camera LVM-2630

The LVM-2630 has 1920 actual physical contour points in the X-direction, the maximum FOV field width is greater than 105 mm, and the Z-direction depth of field is 84 mm. The acquisition speed under full frame is as high as 2500 frames per second and up to 56000 frames per second, which is suitable for high-precision and high-speed measurement of screw holes of mobile phones.

(LVM-2630 series camera parameters)

3.3 Detection method

Using 3D point cloud data, measure the height difference data of the specified screw position.

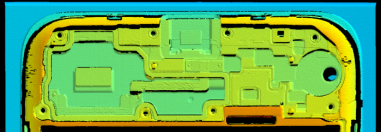

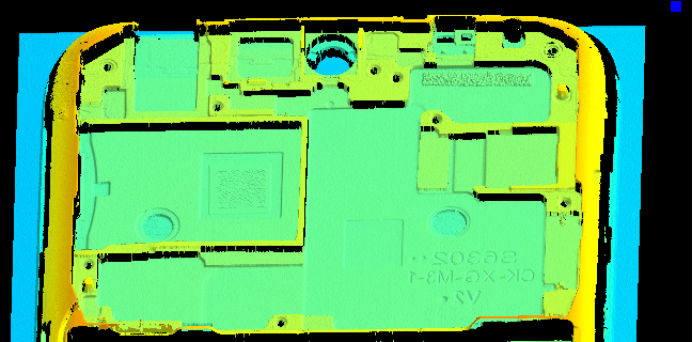

(Partial view)

3.4 Mapping effect

(local point cloud map)

3.5 Test Results

( Mobile phone screw hole height repeatability test data)

4. Nextsight Advantage

1)A full range of product lines with independent intellectual property rights: 3D cameras with high precision, high speed and high stability, the performance indicators have reached the international first-class level, the measurement repeatability is within 0.1 micron, and the scanning speed can reach up to 56000Hz;

2)It has the industry-leading 3D vision solution capabilities: the algorithm system is powerful and can be used for multi-channel point cloud data splicing to help customers achieve technological innovation;

3)Rich application scenarios: customized 3D cameras can be provided to meet various on-site inspection and measurement environments, and have been widely used in consumer electronics, new energy batteries, automobile manufacturing, sheet metal processing and other fields.

2022/06/29

2022/06/29