Series applications of 3D smart sensors in battery manufacturing

Series 1: Lithium battery cell detection

1. background knowledge

In recent years, under the influence of carbon emission pressure, the policy support for new energy vehicles in various countries has continued to strengthen. The share of new energy vehicles in the overall automobile market has increased year by year. The most important component of new energy vehicles is the power battery, so the market competition for lithium batteries is becoming more and more fierce. The power battery is composed of cells one by one, so it is necessary to control each cell in terms of quality.

After the lithium battery is produced by two different processes of winding or stacking, it presents three different shapes in terms of the material and shape of the shell package: cylinder, square and soft package. Among them, the square battery is produced in the form of lamination process. It has the advantages of low battery internal resistance, long life, high space utilization, and small decrease in energy density after grouping. In addition, the aluminum casing of the square lithium battery pack has a better protective effect on the cell than the soft-packed aluminum-plastic film battery. Provide long-term, high cruising range, and instant output stable power source for electric vehicles, which can effectively improve the safety of vehicle power batteries.

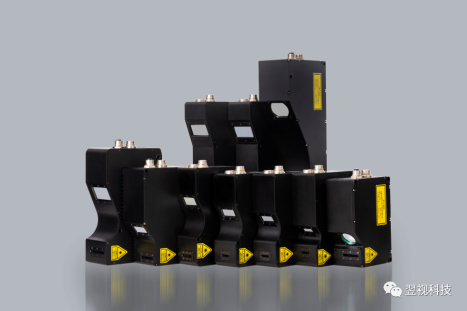

Today, I will introduce to you the application cases of LVM -2600 series cameras in the lithium battery industry!

2. Cell top cover weld inspection

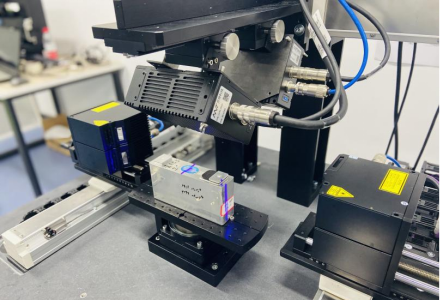

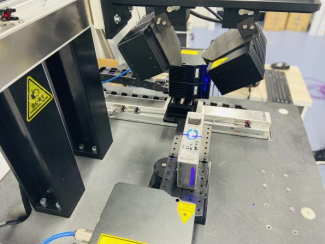

(Environmental construction physical map)

2.1 Demand Analysis

detection of battery top cover welds

2.2 Using the camera

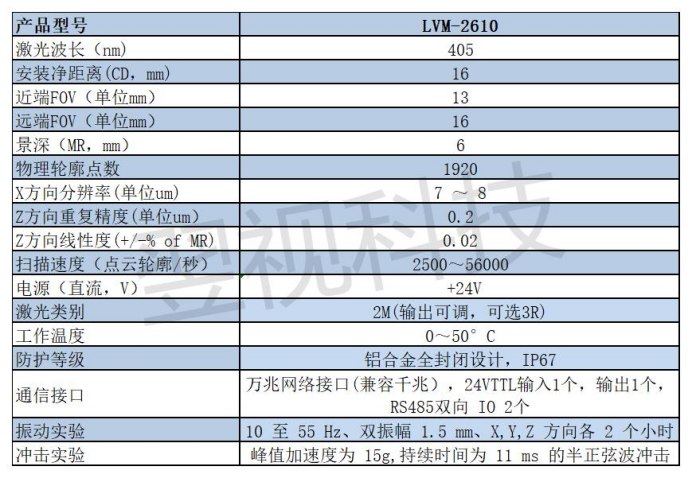

Integrated 3D Line Laser Camera LVM-2610

LVM-2610 has 1920 actual physical contour points in the X direction , and outputs up to 4096 points in depth map mode. The acquisition speed of the full frame is 2500 frames per second, and the maximum can reach 56000 frames per second, which is suitable for high-precision detection.

(LVM-2610 series camera parameters)

2.3 Detection method

The camera tilts the laser to aim at the welding edge of the top cover

The camera-fixed product moves along a straight line for scanning measurement

The mobile platform needs to have a stable encoder signal output

( Material )

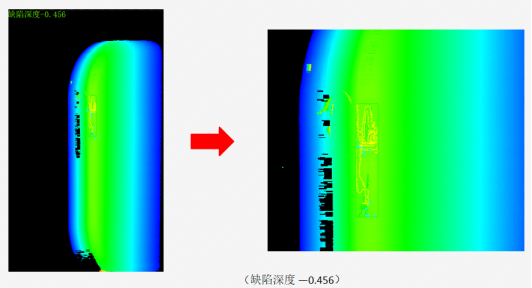

2.4 Drawing effect of leak detection of roof welding seam

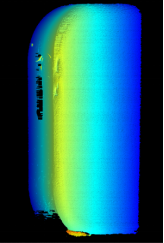

( defect partial physical map ) (point cloud map) (depth map)

Detection results: Defects are extracted through the depth threshold, and the defect depth is -0.456mm.

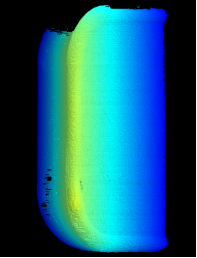

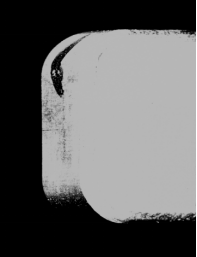

2.5 The effect of detection and mapping of roof welding seam bulge

(point cloud map) ( Intensity graph)

Detection results: Defects are extracted through the depth threshold, and the defect depth is 0.700mm.

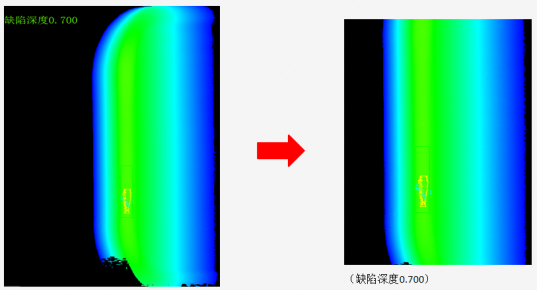

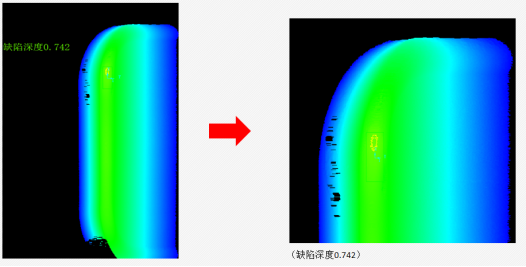

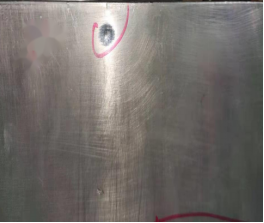

2. 6 The effect of the top cover weld explosion point detection map

( defect partial physical map ) ( point cloud map ) (intensity map)

Detection results: Defects are extracted by depth threshold, and the depth of defects is 0.742mm.

3. Large surface and side inspection of battery cells

(Environmental construction physical map)

3.1 Demand Analysis

Scratches on the large surface and side of the cell, electrolyte inspection, pits , deformation, foreign body detection

3.2 Using the camera

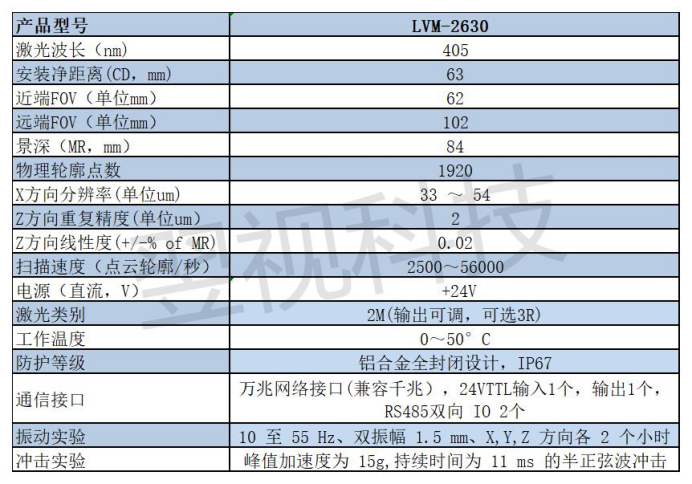

Integrated 3D Line Laser Camera LVM-2630

The LVM-2630 has 1920 actual physical contour points in the X direction, and outputs up to 4096 points in depth map mode . The maximum FOV field width is greater than 10 2 mm, and the Z-direction depth of field is 84 mm. The acquisition speed under full frame is as high as 2500 frames per second and up to 56000 frames per second, which is suitable for high-precision and high-speed measurement of lithium battery cells .

(LVM-2630 series camera parameters)

3.3 Detection method

· Using four LVM2630 splicing methods for inspection

The camera-fixed product moves along a straight line for scanning measurement

The mobile platform needs to have a stable encoder signal output

3.4 Effect of cell scratch detection and mapping

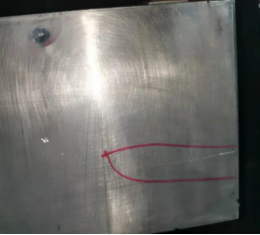

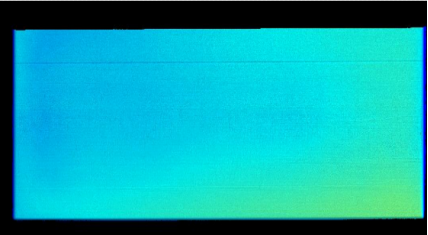

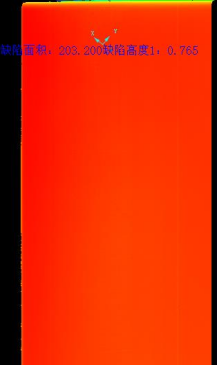

( defect partial physical map ) (local point cloud map)

Detection results: Defects are extracted through the depth threshold, there are 1 defect in total, defect area: 203.200mm , defect height: 0.765mm .

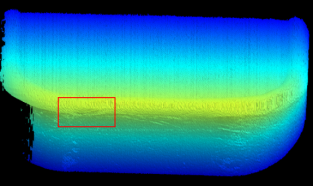

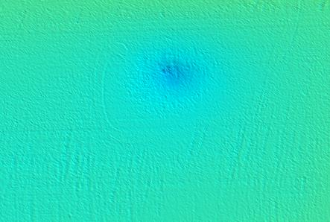

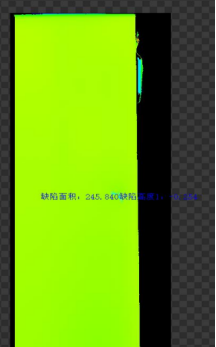

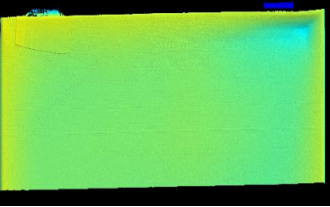

3.5 The effect of cell pit detection and mapping

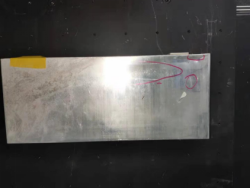

( defect partial physical map ) (local point cloud map)

Detection results: Defects are extracted through the depth threshold, there are 1 defect in total, defect area: 245.840mm , defect height: -0.254mm .

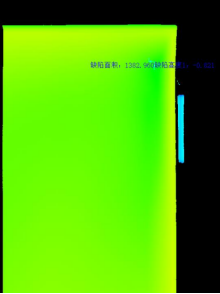

3. 6 Effect of cell deformation detection and mapping

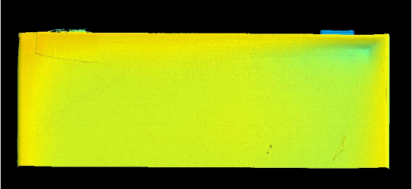

( defect partial physical map ) (point cloud map)

Detection results: Defects are extracted through the depth threshold, there are 1 defect in total, defect area: 1382.96mm , defect height: -0.821 mm .

3. 7 Effect of cell foreign body detection and drawing

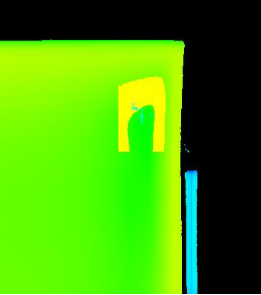

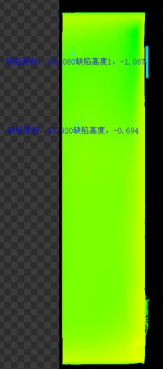

( physical picture ) (point cloud map)

Detection results: Defects are extracted through the depth threshold, there are 2 defects in total, defect area: 376.080mm , 53.920mm , defect height: -1.087mm , -0.694mm .

4. Nextsight Advantage

1)A full range of product lines with independent intellectual property rights: 3D cameras with high precision, high speed and high stability, the performance indicators have reached the international first-class level, the measurement repeatability is within 0.1 micron, and the scanning speed can reach up to 56000Hz;

2)It has the industry-leading 3D vision solution capabilities: the algorithm system is powerful and can be used for multi-channel point cloud data splicing to help customers achieve technological innovation;

3)Rich application scenarios: customized 3D cameras can be provided to meet various on-site inspection and measurement environments, and have been widely used in consumer electronics, new energy batteries, automobile manufacturing, sheet metal processing and other fields.

2022/07/05

2022/07/05