1. background knowledge

In recent years, under the influence of carbon emission pressure, the policy support for new energy vehicles in various countries has continued to strengthen. The share of new energy vehicles in the overall automobile market has increased year by year. The most important component of new energy vehicles is the power battery, so the market competition for lithium batteries is becoming more and more fierce.

The production of battery modules has the characteristics of high-speed online high-precision detection, which requires the camera to meet the high-speed point cloud data acquisition and processing of more than 10K frames per second of point cloud contours. The LVM-2600 series launched by Nextvision Technology has high-speed acquisition performance of up to 56K point cloud contours per second, especially its innovative implementation of 10 Gigabit Ethernet data transmission and processing in the industry, which can transmit original point cloud data at high speed.

2. Full-scale inspection of new energy power battery modules

(Environmental construction physical map)

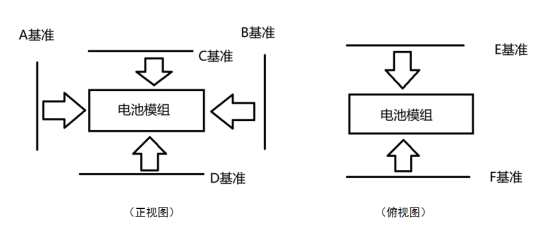

principle

l Benchmark A to Benchmark B is the length of the calibration block

l Benchmark C to Benchmark D is the length of the calibration block

l Reference E to reference F are the length of the calibration block

battery module = the length of the calibration block - the distance from the A reference to the left side of the battery module - the distance from the B reference to the right side of the battery module, the width of the battery module = the width of the calibration block - the distance between the C reference and the bottom of the battery module - D reference to the battery The distance above the module

Height of battery module = height of calibration block - distance from reference E to the bottom of the battery module - distance from reference to the top of the battery module

2.1 Demand analysis

Six-sided dimension inspection of battery modules

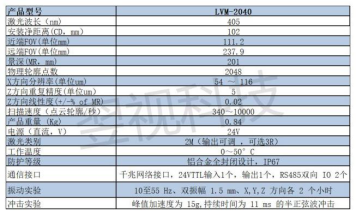

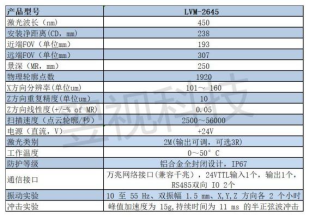

2.2 Using the camera

LVM-2040 and LVM-2645 cameras (with the help of 2D cameras to complete the diameter and position detection of end plate holes/electrode holes) can meet the six-sided size detection requirements of battery modules. On the premise of ensuring image effects and detection accuracy, they can fully Meet the scanning speed of 10K or more.

(LVM-2 040 camera parameters) (LVM-2 645 camera parameters)

3.3 Detection method

3D inspection, both ends and both sides of the module are detected by the LVM-2040 camera to detect the length, width and feature size of the battery. The LVM-2645 camera detects the height of the module and the direction of the height of the end plate. Using the NVT-Proc image algorithm platform, If there is no defect, it is judged as OK, otherwise it is judged as NG;

4. Detection effect

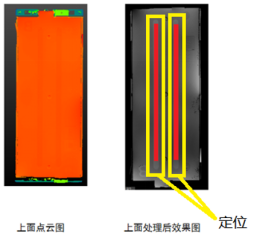

4.1 Measuring the total length of the module

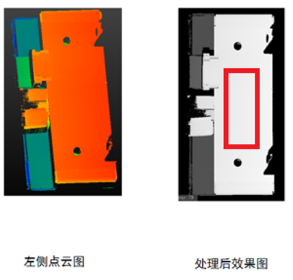

Ø First, use two round holes to locate to ensure that the ROI does not move relative to the product. Take the red ROI box area in the left picture, and calculate the average distance from the points in the ROI box to the reference plane;

Ø First, use two round holes to locate the position to ensure that the ROI does not move relative to the product. Take the red ROI box area in the right picture and calculate the average distance from the points in the ROI box to the reference plane;

Ø The length of the battery module = the length of the calibration block - the distance from the reference A to the left side of the battery module - the distance from the reference B to the right side of the battery module

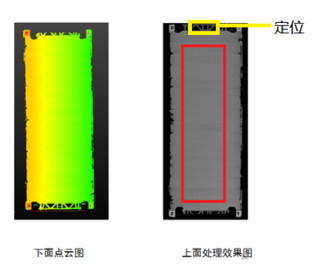

4.2 Overall width measurement of module

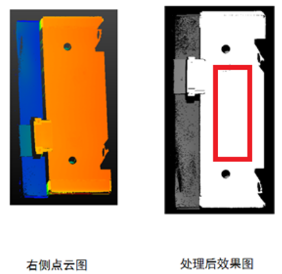

Ø First use the feature points to locate, to ensure that the ROI does not move relative to the product, take the red ROI box area in the left picture, and calculate the average distance from the points in the ROI box to the reference plane;

Ø First use feature points to locate, to ensure that the ROI does not move relative to the product, take the red ROI box area in the right picture, and calculate the average distance from the points in the ROI box to the reference plane;

Ø The length of the battery module = the width of the calibration block - the distance from the C reference to the left side of the battery module - the distance from the D reference to the right side of the battery module

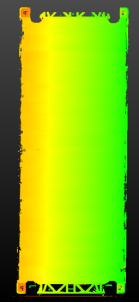

4.3 Overall height measurement of modules

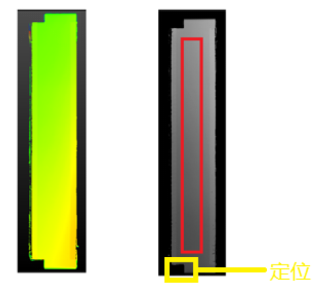

Ø First use the feature points to locate, to ensure that the ROI does not move relative to the product, take the red ROI box area in the left picture, and calculate the average distance from the points in the ROI box to the reference plane;

Ø First use feature points to locate, to ensure that the ROI does not move relative to the product, take the red ROI box area in the right picture, and calculate the average distance from the points in the ROI box to the reference plane;

Ø The length of the battery module = the height of the calibration block - the distance from the E reference to the left side of the battery module - the distance from the F reference to the right side of the battery module

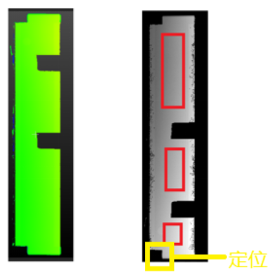

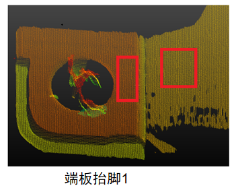

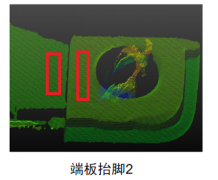

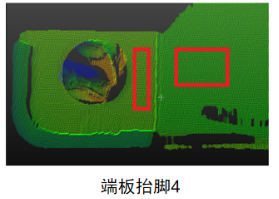

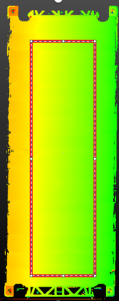

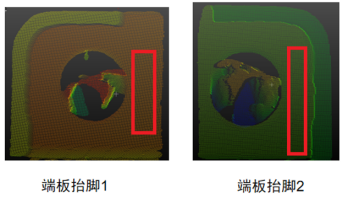

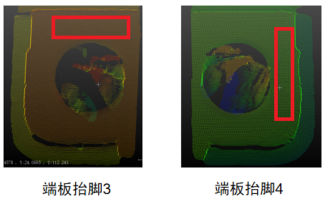

4.4 Height measurement of foot lift of end plate

Ø Take the round hole as the feature point positioning to ensure that the ROI frame relative to the product position remains unchanged. Take the ROI of the red area on the bottom surface of the module, fit the ROI area into a plane, first filter to remove the noise in the ROI frame, and then find the average distance from the point in the ROI area on the end plate lift to the fitting plane.

4.5 Measurement of the flatness of the bottom surface

Ø Grab the feature point positioning to ensure that the ROI does not move relative to the product, take the ROI of the bottom surface of the module, fit the ROI area into a plane with the least squares method, and calculate the flatness of the bottom surface.

4.6 Measurement of the flatness of the bottom surface

Ø Using each circular hole area as a feature, position each module to obtain the position of the module in the image (ensure that when the position of the battery module changes, the location of the sampling point is relatively fixed with the position of the module);

Ø According to the module position information, fit the four ROI frame areas into a plane, and then calculate the flatness.

5. NextView Advantage

1)A full range of product lines with independent intellectual property rights: 3D cameras with high precision, high speed and high stability, the performance indicators have reached the international first-class level, the measurement repeatability is within 0.1 micron, and the scanning speed can reach up to 56000Hz;

2)It has the industry-leading 3D vision solution capabilities: the algorithm system is powerful and can be used for multi-channel point cloud data splicing to help customers achieve technological innovation;

3)Rich application scenarios: customized 3D cameras can be provided to meet various on-site inspection and measurement environments, and have been widely used in consumer electronics, new energy batteries, automobile manufacturing, sheet metal processing and other fields.

6. Contact us

headquarters

15th Floor, Building 1, Tsinghua Science and Technology Park, No. 119 Zicheng Road, Yinzhou District, Ningbo City

R & D Center

Room B2, 8th Floor, Block B, Kehai Building, No. 800 Naxian Road, Zhangjiang Science City, Pudong New Area, Shanghai

East China Sales and Technical Support Center

Room 1705-1706, 17th Floor, East Building, Building A, Fanhua Center, Xiangcheng District, Suzhou

South China Sales and Technical Support Center

Room 1001, 10th Floor, Yonghui International Business Building, Baoan District, Shenzhen

contact number:

0574-55337778

Company official website:

www.nextvision-tech.com

Company email:

info@nextvision-tech.com

2022/07/08

2022/07/08