1. Background knowledge

Under the influence of multiple factors such as 5G, the Internet of Things and the rapid development of the Internet home improvement market, China's smart home market has shown a vigorous development trend. As the main raw material in the upstream of the home furnishing industry, wood covers 70% of the midstream products of the industry, including floors, various cabinets, furniture, etc. At the same time, the quality of the board determines the price of home furnishing products, so the woodworking production line is also the core production line of the home furnishing industry. , the quality of wood is one of the important indicators to assess the quality of wood.

With the development of Industry 4.0, more and more large home furnishing enterprises, especially flooring and cabinet enterprises, are accelerating the improvement of the intelligence of woodworking production lines, integrating the processes of cutting, edge sealing, drilling, sorting, and packaging. In recent years, more and more attention has been paid to the processing quality of the sheet, especially the surface defects. Wood defects mainly include ten categories: knots, discoloration, rot, insect damage, cracks, trunk shape defects, wood structural defects, scars, wood processing defects and deformation. Therefore , in order to improve the utilization rate of wood, the use of machine vision to achieve rapid and stable detection of wood defects can not only overcome the disadvantages of low manual detection efficiency, high labor intensity, and low accuracy, but also play an important role in improving the intelligence level of wood processing enterprises. significance.

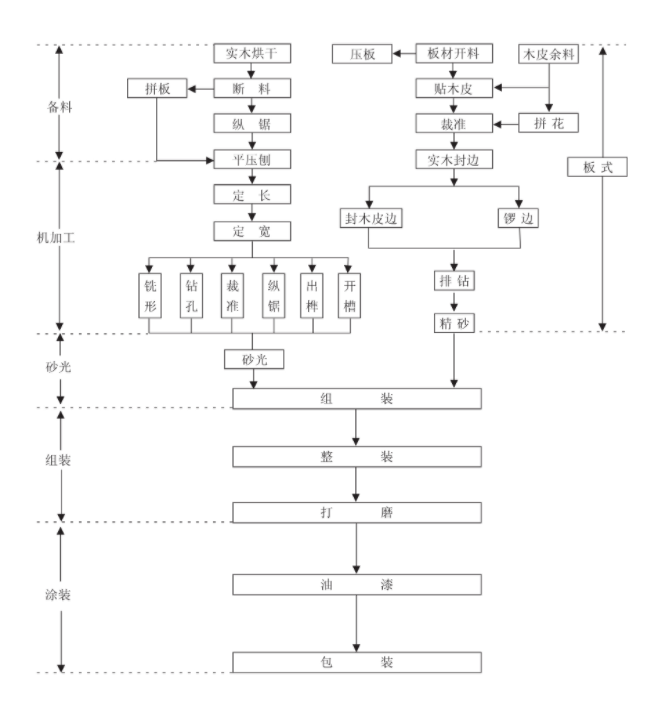

Second, the main production process introduction

The woodworking process in the home furnishing industry is cumbersome and involves many processes. The main core steps can be divided into 4 steps: ingredients, processing, assembly, and painting .

1、preparation step : select the incoming log material, and form wool material through multi-step and multi-process operation;

Quality control requirements for material preparation: material quality (burrs, tears, dents, indentations, worm holes, decay, deformation, knots, etc.), moisture content, size, grain size and direction, pressurization time, etc.;

2、Processing steps : the process of processing the wool according to the shape and size required by the design drawings;

Quality control requirements for processing: mainly to ensure the size, shape and wood quality, as well as the quality of the glue amount;

3、Assembly step : the process of assembling multiple components to form the final form of the finished product;

Assembly quality control requirements: missing parts and assembly quality inspection;

4、Coating step : the process of final painting the finished product;

Coating quality control requirements: control and inspection of spraying quality;

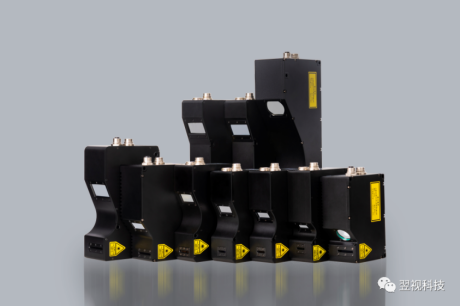

三、The application of LVM line laser products of Yishi Technology

Sheet surface defect detection :

The surface defects of the board affect the quality of the board, so it is necessary to detect and monitor the board defects (such as corner defects, cracks, foreign objects, etc.) before the board assembly process.

Detection difficulties:

Accurately obtain images of surface defects by using the principle of laser scattering;

High-precision, large-format inspection requires multi-camera stitching;

The imaging of wood knots needs to be distinguished from defects;

Detection method

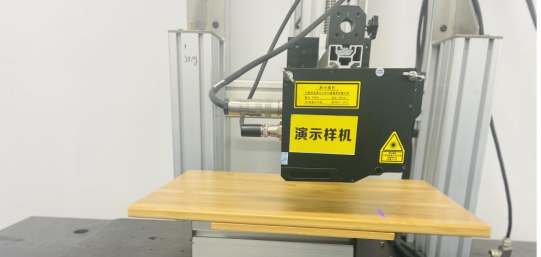

NextVision LVM-2600 series cameras are fixed and the wood moves along a straight line on a mobile platform for inspection.

(Measurement real picture)

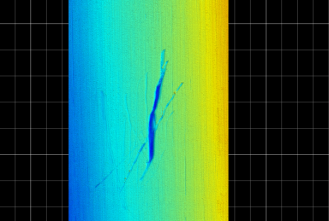

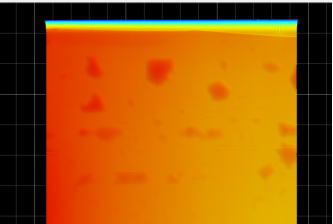

Mapping effect

( scratches ) ( bubble )

The following is a demonstration of the shooting effect of LVM-2600 series cameras in wood inspection (video): You can search for the first video number of Nextvision Technology and put it in

Fourth, the advantages of nextvision

1)A full range of product lines with independent intellectual property rights: 3D cameras with high precision, high speed and high stability, the performance indicators have reached the international first-class level, the measurement repeatability is within 0.1 micron, and the scanning speed can reach up to 56000Hz;

2)It has the industry-leading 3D vision solution capabilities: the algorithm system is powerful and can be used for multi-channel point cloud data splicing to help customers achieve technological innovation;

3)Rich application scenarios: customized 3D cameras can be provided to meet various on-site inspection and measurement environments, and have been widely used in consumer electronics, new energy batteries, automobile manufacturing, sheet metal processing and other fields.

contact us Contact us

headquarters

15th Floor, Building 1, Tsinghua Science and Technology Park, No. 119 Zicheng Road, Yinzhou District, Ningbo City

R & D Center

Room B2, 8th Floor, Block B, Kehai Building, No. 800 Naxian Road, Zhangjiang Science City, Pudong New Area, Shanghai

Subsidiary

Room 1705-1706, 17th Floor, East Building, Building A, Fanhua Center, Xiangcheng District, Suzhou

Shenzhen Office

Room 1001, 10th Floor, Yonghui International Business Building, Baoan District, Shenzhen

contact number:

0574-55337778

Company official website:

www.nextvision-tech.com

Company email:

info@nextvision-tech.com

2022/07/12

2022/07/12