background knowledge

In the new era, 3C electronic products such as mobile phones have become an indispensable part of people's lives. Based on the high pursuit of product performance and quality by the public, the application of machine vision inspection in the 3C electronic manufacturing industry has gradually increased.

China is a big manufacturing country. Driven by favorable policies, technological progress and market demand, China's 3C electronics industry (including communications, consumer electronics, computers, mobile phones, smart watches , etc.) has developed rapidly and has become one of China's important pillar industries. New products and technologies continue to emerge, and the market size of 3C electronic products continues to expand. In order to effectively improve production capacity and product quality, machine vision equipment is gradually replacing labor and is widely used in the 3C electronic product manufacturing industry.

The 3C electronics industry is the field with the largest scale of machine vision applications in China. The machine vision products of Yishi Technology are suitable for all aspects of the 3C electronics industry chain, covering from incoming inspection of electronic components, IC chip manufacturing, packaging, PCB printed circuit board production, Inspection, assembly, SMT patch processing, component assembly, whole machine assembly, packaging and other manufacturing links help users reduce costs and increase efficiency.

Today I will introduce to you the application cases of Nextvision LVM series cameras in the 3C industry!

Applications

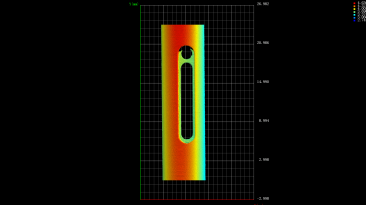

1. Depth detection of mobile phone SIM card slot

Client: An internationally renowned mobile phone parts brand supplier

Workpiece: Mobile phone parts

Downstream Industry: Consumer Electronics Industry

Item model number: LVM-2010

Technical requirements: Detect the depth from the highest point of the arc on the outer surface of the mobile phone to the inner plane of the SIM slot,

Accuracy requirements: repeatability 0.01mm, detection efficiency: 3s ;

Solution: Z-direction repeatability 0.2um, X-direction resolution 7-9um, field of view 15-

18mm, depth of field 10mm ;

Customer value: It can meet customer requirements and detect the depth of the SIM card slot efficiently and stably .

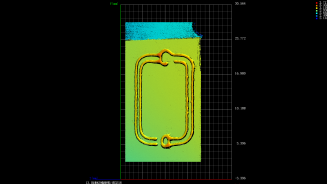

2. Glue height detection on the back of the smart bracelet

Client: A well-known electronic technology company

Workpiece: smart bracelet wearable device

Downstream Industry: Electronics Industry

Item model number: LVM-2510

Technical requirements: Detect the glue on the back of the bracelet; measure the glue height;

Customer value: Realize 3D glue road measurement and improve product quality.

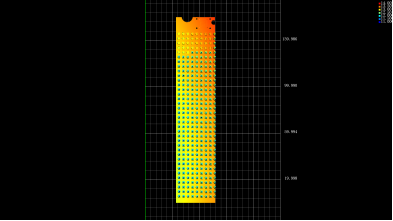

3、Smart watch parts level difference measurement

Client: Well-known electronic intelligent manufacturer

Artifact: Apple Watch smartwatch

Downstream Industry: Electronic 3C Industry

Item model number: LVM-2010

Technical requirements: measurement step difference (the highest Z value of the dot to the height of the fitting datum) ;

Customer value: realize automatic measurement and improve product quality.

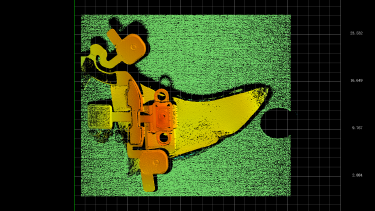

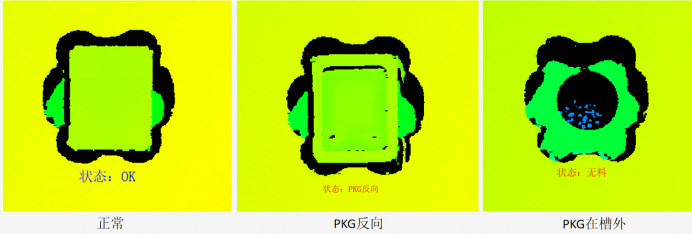

4、Wafer pose detection

Client: Well-known Electronics Co., Ltd.

Workpiece: Wafer

Downstream industry: 3C electronics industry

Item model number: LVM-2520

Technical requirements: 1. Able to judge, report to the police or pick out according to the needs of bad phenomena such as the reverse of the left PKG, the PKG is shifting, the PKG is outside the slot, the CAP&PKG is outside the slot, and the PKG is shifting ;

The detection time should be completed within 60S ;

Customer value: Eliminate manual testing, realize fully automatic testing, and improve the consistency of testing results.

About Us

Founded in 2017, Yishi Technology is a high-tech enterprise integrating industrial visual product design, research and development, production, sales and service. The company focuses on the underlying algorithm development and hardware implementation of industrial vision products, and has a full set of software and hardware technologies with independent intellectual property rights. Aiming to become the world's leading vision sensor company.

in the field of intelligent manufacturing

The LVM (Laser Vision Measurement) series of 3D smart sensors developed by NextVision harden the industry-leading 3D imaging algorithm in the chip to achieve high-speed and high-performance measurement . Import substitution can be achieved. At present, the company's products have been widely used in consumer electronics manufacturing, new energy manufacturing, automobile manufacturing, sheet metal processing, wood processing, food and beverage and other fields.

Contact us

Headquarters

15th Floor, Building 1, Tsinghua Science and Technology Park, No. 119 Zicheng Road, Yinzhou District, Ningbo City

R & D Center

Room B2, 8th Floor, Block B, Kehai Building, No. 800 Naxian Road, Zhangjiang Science City, Pudong New Area, Shanghai

East China Sales and Technical Support Center

Room 1705-1706, 17th Floor, East Building, Building A, Fanhua Center, Xiangcheng District, Suzhou

South China Sales and Technical Support Center

Room 1001, 10th Floor, Yonghui International Business Building, Baoan District, Shenzhen

contact number:

0574-55337778

Company official website:

www.nextvision-tech.com

Company email:

info@nextvision-tech.com

2022/08/19

2022/08/19