I. Background knowledge

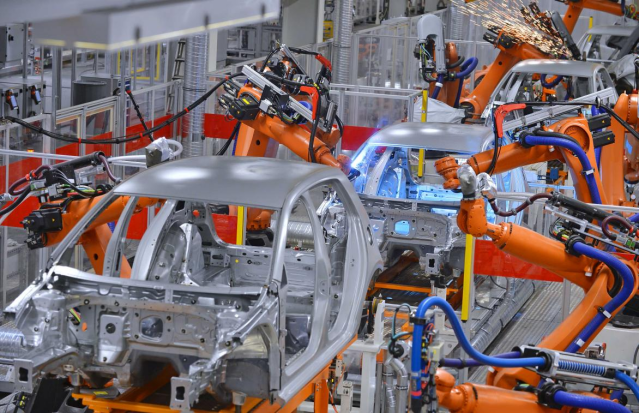

The automotive industry is a high-tech industry with a relatively high degree of automation, and many advanced automation technologies have been successfully applied to various production processes in the industry. Many aspects of automobile manufacturing have achieved unmanned operation, which requires a reliable detection technology to verify the correctness of each assembly and the eligibility of assembly parts.

Machine vision is deployed in a variety of industrial and consumer applications to bring efficiency, innovation, and advances in automation. Compared with the traditional detection methods, machine vision detection has a strong ability to adapt to the harsh environment of the industrial production site, has a higher cost performance, universal industrial interface and relatively high fault tolerance and security.Among them, the automotive industry is one of the earliest industries to adopt automated machine vision technology.The application of machine vision technology has run through the whole automobile manufacturing process, including the development from the initial quality inspection of raw materials to the 100% on-line measurement of automobile parts, and then the control of welding, gluing, punching and other processes in the manufacturing process, and finally the quality control of the body assembly and the whole vehicle leaving the factory.

二、Process flow of automobile industry

The production process of automobile is a very complex and huge industrial production, involving many types of workshops and types of work. Briefly speaking, automobile production mainly includes six parts: stamping, welding, painting, power assembly, assembly and testing.

First: Stamping process (producing various body stamping parts)

Second: Welding process (welding various body stamping parts into a finished body)

The third: painting process (to prevent the body from rusting, so that the body has a beautiful appearance)

Fourth: Powertrain process (production and assembly of engine and gearbox through forging)

Fifth: Final assembly process (assemble the body, chassis and interior parts together to form a complete car)

Sixth: Inspection process (potential quality problems in the production and assembly process are found, and unqualified products are rejected as far as possible)

三、Application of LVM Line Laser Products of Nextvision tech

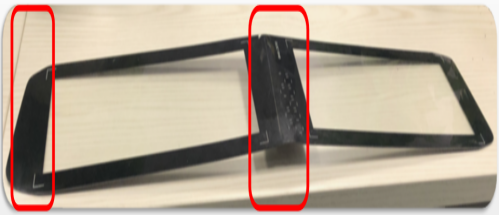

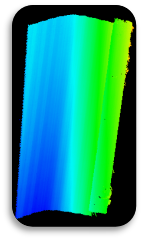

1. Window frame curved surface angle detection

Customer: Famous Auto Parts Co., Ltd.

Workpiece: Automotive Parts

Downstream industry: automobile industry

Model: LVM-2030

Technical requirements: detect the angle of curved surface

Customer value: In the past, three-coordinate measurement was done manually, but now the machine is automated to improve stability.

(Physical drawing)

(Point cloud image)

2. Auto parts inspection

Client: a listed auto parts company

Downstream industry: auto parts

Model: LVM-2640

Technical requirements: take the plastic at the bottom of the column as the reference plane, and detect the depth information from the top plane of each Pin to the reference plane.

Customer value: eliminate manual inspection, replace coordinate sampling inspection, realize automatic inspection and improve product quality

(Physical image) (Point cloud image)

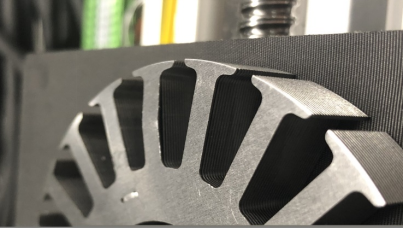

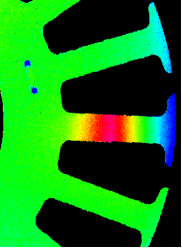

3. Auto parts inspection

Client: Shanghai Automation Equipment Company

Workpieces: shaft gear component

Downstream industry: auto parts

Model: LVM-2040

Technical requirements: sample defect detection, detection range 100mm X 100mm, Z-direction accuracy requirement 0.05-0.1mm

Customer value: eliminate manual detection, realize automatic detection, high-speed and stable detection of sample point cloud

(Physical image) (Point cloud image)

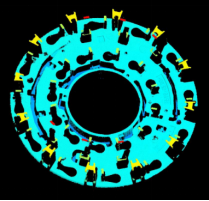

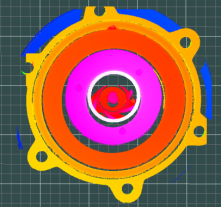

4. Oil pump detection

Customer: Famous Auto Parts Co., Ltd.

Workpiece: Automobile oil pump

Downstream industry: automobile industry

Model: LVM-2030

Technical requirements: check whether there is o-ring in the oil pump and the number of gaskets

Customer value: In the past, three-coordinate measurement was done manually, but now the machine is automated to improve stability.

(Physical drawing) (O-rings are OK or not)

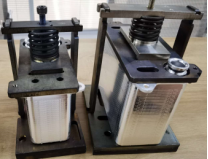

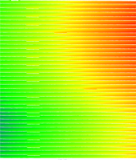

5. Fin height detection

Customer: Global leading enterprise in new energy thermal management industry

Part: Heat exchanger in an international automobile air conditioner

Downstream industry: new energy auto parts

Model: LVM-2040

Technical requirements: check the number of laminations, lamination sequence and lamination distance of each product

Camera accuracy: 0.005 mm

Customer value: Scan the products within 2 seconds, quickly detect whether the lamination quantity, lamination sequence and lamination distance of each product are OK, eliminate manual detection, realize full-automatic detection, improve product quality and enhance the consistency of detection results.

(Physical image) (Point cloud image)

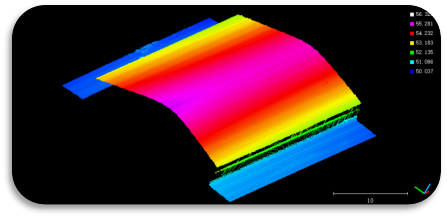

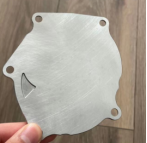

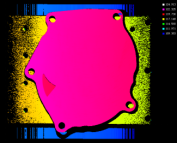

6. Flatness detection of precision instruments and equipment aluminum products

Customer: Shanghai Precision Instrument Equipment Co., Ltd.

Workpiece: Aluminum products

Downstream industry: automobile industry

Model: LVM-2040

Technical requirements: the accuracy is required to be 0.03 mm, and the flatness is measured.

Customer value: In the past, three-coordinate measurement was done manually, but now the machine is automated to improve stability.

(Physical image) (Point cloud image)

About Us

Founded in 2017, Next Vision Tech is a high-tech enterprise integrating industrial visual product design, research and development, production, sales and service. The company focuses on the underlying algorithm development and hardware implementation of industrial vision products, and has a complete set of software and hardware technologies with independent intellectual property rights. The goal is to become the world's leading vision sensor company.

In the field of intelligent manufacturing

The LVM (Laser Vision Measurement) series 3D intelligent sensor developed by Next Vision Tech hardens the industry-leading 3D imaging algorithm in the chip to achieve high-speed and high-performance measurement. Its repeatability accuracy reaches 0.1 micron. The performance index of the product exceeds that of foreign counterparts and can be replaced by imports.At present, the company's products have been widely used in consumer electronics manufacturing, new energy manufacturing, automobile manufacturing, sheet metal processing, wood processing, food and beverage and other fields.

Contact us

Headquarters

Floor 15, Building 1, Tsinghua Kechuang Park, 119 Zicheng Road, Yinzhou District, Ningbo City

Research and Development Center

Room B2, 8/F, Block B, Kehai Building, 800 Naxian Road, Zhangjiang Science City, Pudong New Area, Shanghai

East China Sales and Technical Support Center

Room 1705-1706, 17/F, East Block, Building A, Fanhua Center, Xiangcheng District, Suzhou

South China Sales and Technical Support Center

Room 1001, 10/F, Yonghui International Business Building, Baoan District, Shenzhen

Contact number:

0574-55337778

Company official website:

www.nextvision-tech.com

Company Email:

info@nextvision-tech.com

2022/09/16

2022/09/16