I. Background knowledge

The tire is one of the important parts of the automobile, it contacts with the road surface directly, and alleviates the impact suffered when the automobile is running together with the automobile suspension, so as to ensure that the automobile has good riding comfort and driving smoothness, ensure that the wheel and the road surface have good adhesion, and improve the traction, braking and trafficability of the automobile;Bearing the weight of the car, the role of tires on the car is crucial.

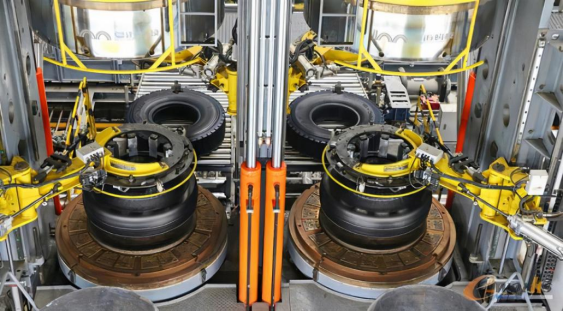

Tire manufacturing is a complex process, including many steps, and there are strict requirements for quality control in the whole manufacturing process.However, in the automatic production process of tires, it is inevitable that a small part of tires will have some defects, such as unqualified size, scratches, bulges, etc. In some processes, it is also necessary to detect the pattern of tires, DOT character recognition, etc. All of these require visual intervention.Nowadays, more and more automobile tire production lines are introducing visual inspection to check the quality of tires.

2. Application of LVM Line Laser Products in Tire Quality Inspection

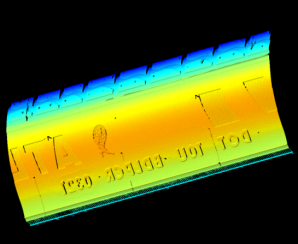

1. Tire DOT code identification: The 3D sensor generates a height map by scanning the tire, which is used to identify the DOT code on the tire sidewall, and the character image can be clearly displayed.

Detection method

The LVM-2040 camera is fixed on the mobile platform and moves clockwise or counterclockwise along the tire for detection.

(Physical map of measurement)

Detection equipment

Test camera: LVM-2040

Scan line width: 111-234 mm

Sampling interval in Y direction: 0.05

Scanning mode: fixed camera and moving workpiece

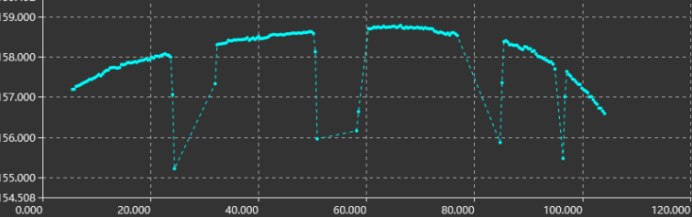

Map collection effect

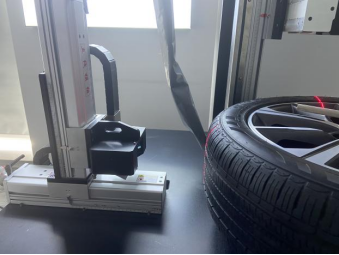

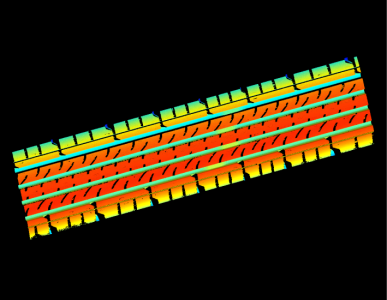

2. Detection of tread section size: The 3D sensor generates a height map by scanning the tire, which is used to measure the key dimensions of the tread, such as thickness profile, total width, shoulder width, middle width, shoulder thickness and middle thickness.

Detection method

The LVM-2040 camera is fixed on the mobile platform and moves clockwise or counterclockwise along the tire for detection.

(Physical map of measurement)

Detection equipment

Test camera: LVM-2040

Scan line width: 111-234 mm

Sampling interval in Y direction: 0.05

Scanning mode: fixed camera and moving workpiece

Map collection effect

About Us

Founded in 2017, Next Vision Tech is a high-tech enterprise integrating industrial visual product design, research and development, production, sales and service. The company focuses on the underlying algorithm development and hardware implementation of industrial vision products, and has a complete set of software and hardware technologies with independent intellectual property rights. The goal is to become the world's leading vision sensor company.

In the field of intelligent manufacturing

The LVM (Laser Vision Measurement) series 3D intelligent sensor developed by Next Vision Tech hardens the industry-leading 3D imaging algorithm in the chip to achieve high-speed and high-performance measurement. Its repeatability accuracy reaches 0.1 micron. The performance index of the product exceeds that of foreign counterparts and can be replaced by imports.At present, the company's products have been widely used in consumer electronics manufacturing, new energy manufacturing, automobile manufacturing, sheet metal processing, wood processing, food and beverage and other fields.

Contact us

Headquarters

Floor 15, Building 1, Tsinghua Kechuang Park, 119 Zicheng Road, Yinzhou District, Ningbo City

Research and Development Center

Room B2, 8/F, Block B, Kehai Building, 800 Naxian Road, Zhangjiang Science City, Pudong New Area, Shanghai

East China Sales and Technical Support Center

Room 1705-1706, 17/F, East Block, Building A, Fanhua Center, Xiangcheng District, Suzhou

South China Sales and Technical Support Center

Room 1001, 10/F, Yonghui International Business Building, Baoan District, Shenzhen

Contact number:

0574-55337778

Company official website:

www.nextvision-tech.com

Company Email:

info@nextvision-tech.com

2022/09/23

2022/09/23