1. Background knowledge

The wheel hub is the rotating part of the wheel core connected by the column, which plays the role of bearing, steering, driving, braking and so on, and is one of the main components of the automobile. Car wheel hub using aluminum alloy wheel hub, because the aluminum products hardness is low, inevitably will appear in the production process of product defects, such as welding slag, wrinkle, pits, deformation, etc., these need machine vision system detection instead of manual identification, to ensure the ideal measurement accuracy and speed, accurate, quickly find quality problems, more can help manufacturing enterprises to make decisions quickly, the control of product quality, effectively solve the problem of productivity.

Today for you to introduce the application of LVM2500 series camera in the appearance detection of the hub!

2. Appearance inspection of automobile wheels

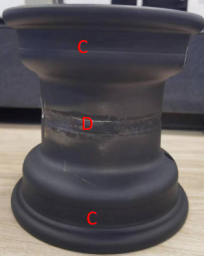

(picture of real products)

(CD face of physical drawing) (plane A of object) (face B of object)

2.1 Requirements analysis

Product name: Car wheel hub

Measurement items: welding slag, burr, stoma wrinkle, pit, deformation, grinding deformation, concave and convex edge, thick and thin edge, large and small edge, orange peel, sand skin mark;

Accuracy requirements: 0.5mm;

2.2 Camera type selection

In view of the above detection requirements, the LVM2540 line laser 3D camera can be competent for this task. LVM2540 It is mainly suitable for high-speed 3D detection of small parts; it can provide 2500Hz full frame acquisition rate, physical contour points, depth spacing sampling 4096 points; the acquisition rate up to 56 KHz, which is an ideal choice for high-speed online detection system; light interference in field detection environment; support Modbus output measurement data, and support communication with PLC.

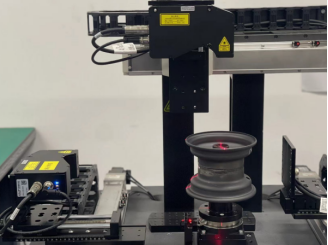

2.3 Detection environment and installation method

l Under 300 LX illumination, the light source is 800~1000mm away from the surface of the measured object;

l The distance between the human eye and the surface of the object is 500mm;

l After the camera is fixed, the product is scanned along the linear circular movement of the center;

l The rotating platform needs to have a stable encoder signal output;

l Use two cameras to scan multiple surfaces;

2.4 Drawing acquisition effect

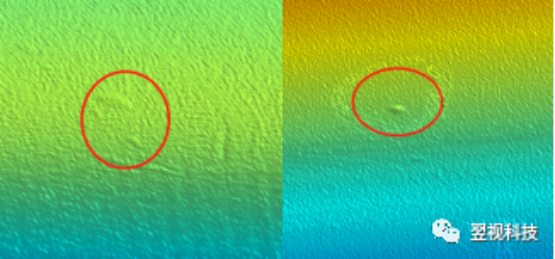

(1) A-face line scanning effect

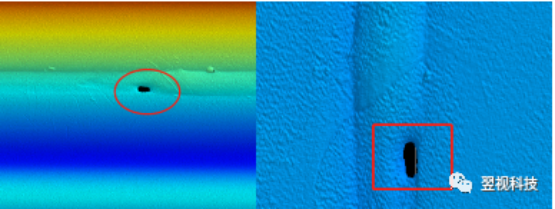

(Gap scan point cloud rendering) (gap scan point cloud rendering)

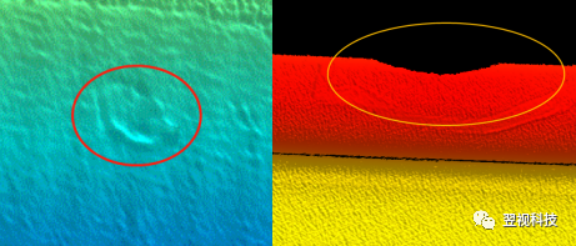

(2)The CD profile scanning effect

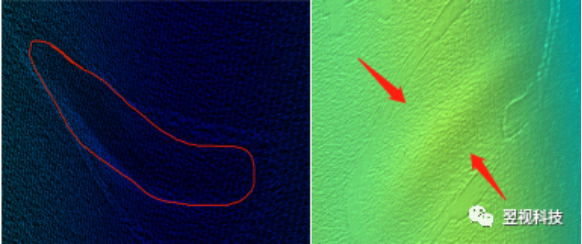

(Pit scanning point cloud effect) (wrinkle scanning point cloud rendering)

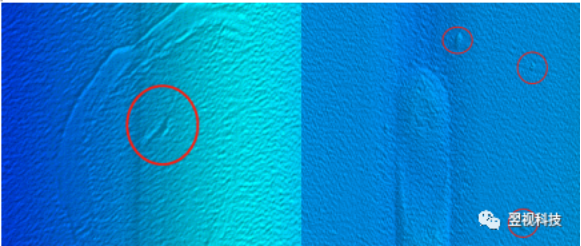

(Burr scanning point cloud effect) (welding slag scanning point cloud effect)

(Dust particle scanning point cloud effect) (welding slag scanning point cloud effect)

(Perforated scanning point cloud effect) (perforated scanning point cloud effect)

3. Test conclusion

The LVM2540-line laser 3D camera of the Next Vision Tech is sure to detect welding slag, burr, air hole wrinkle, pit, deformation, grinding deformation, concave and convex edge, thick thin edge, large and small edge, orange peel, sand skin marks.

Testing value: save manual detection, replace coordinate sampling inspection, realize automatic detection, and improve product quality.

About Us

Founded in 2017, Next Vision Tech is a high-tech enterprise integrating industrial visual product design, research and development, production, sales and service. The company focuses on the underlying algorithm development and hardware implementation of industrial vision products, and has a complete set of software and hardware technologies with independent intellectual property rights. The goal is to become the world's leading vision sensor company.

▲ In the field of intelligent manufacturing

The LVM (Laser Vision Measurement) series 3D intelligent sensor developed by Next Vision Tech hardens the industry-leading 3D imaging algorithm in the chip to achieve high-speed and high-performance measurement. Its repeatability accuracy reaches 0.1 micron. The performance index of the product exceeds that of foreign counterparts and can be replaced by imports.At present, the company's products have been widely used in consumer electronics manufacturing, new energy manufacturing, automobile manufacturing, sheet metal processing, wood processing, food and beverage and other fields.

2023/04/06

2023/04/06