With the development of 3C electronic manufacturing in China, agile manufacturing, flexible manufacturing and lean manufacturing have become the development direction of 3C electronic production enterprises, and the characteristics of machine vision are catering to this development direction and manufacturing trend: high precision, high flexibility, high precision. Whether it is positioning assembly, parts detection, or the whole machine product testing, machine vision has an important role.

Today for you to introduce the LVM 2500 series camera in the appearance of the detection of mobile phone parts!

1. Measurement of flatness of mobile cover and size of screw hole

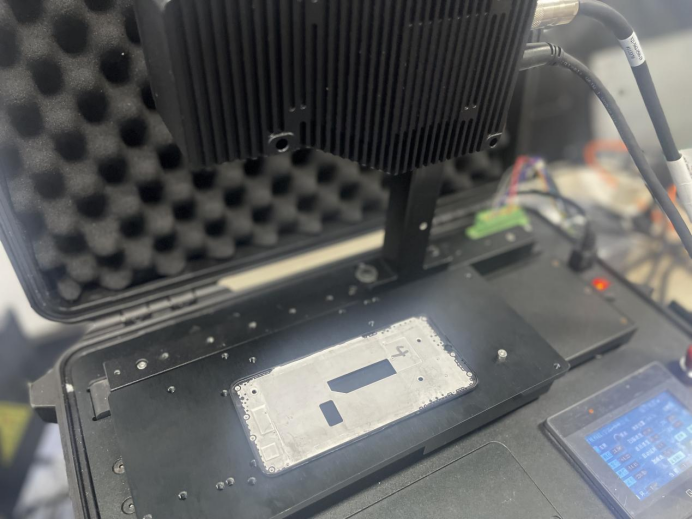

(Physical Figure 1)

2.1 Requirements analysis

(1)Check the flatness of the phone cover

(2)Measure the screw hole in the phone

(3)Dynamic repeatability accuracy: 0.01mm

2.2 Product testing information

(1)Material: aluminum shell

(2)Color: silver white

(3)Dimensions: 70mm * 160mm

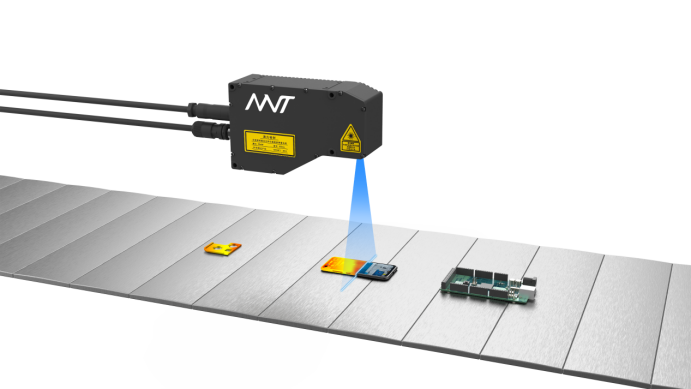

2.3 Camera type selection

For the above detection requirements, YTechnology's LVM2530-line laser 3D camera is capable of this task. LVM2530 Mainly suitable for high-speed 3D detection of small parts; Can provide a 2,500 Hz full-frame acquisition rate, Number of physical contour points, 1,920 points, Depth map uniform spacing sampling maximum 4096 points; Acquisition rate of up to 56 KHz, With a Z-direction repeat accuracy accurate to 0.6 μ m, The Proximal End, 55.4 (FOV), Remote 90.5 (FOV) provides the best target visible, It is the ideal choice of high-speed online detection system; Less affected by the light, Ability to deal with certain light interference in the field detection environment; Support the output measurement data such as Modbus, Supports the communication with the PLC.

2.4 Detection environment and installation method

· After the camera is fixed, the product is scanned and measured along the linear movement of the center;

· The rotating platform needs to have a stable encoder signal output;

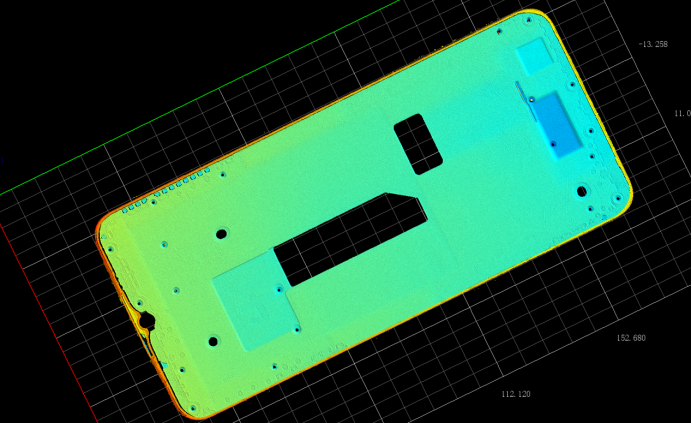

2.5 Drawing acquisition effect

Point cloud map

3. Test conclusion

The LVM2530-wire laser 3D camera is sure to detect the flatness of the mobile phone cover and the size of the screw hole.

Testing value: save manual detection, replace coordinate sampling inspection, realize automatic detection, and improve product quality.

2. Flatdetection and character detection of back cover of mobile phone

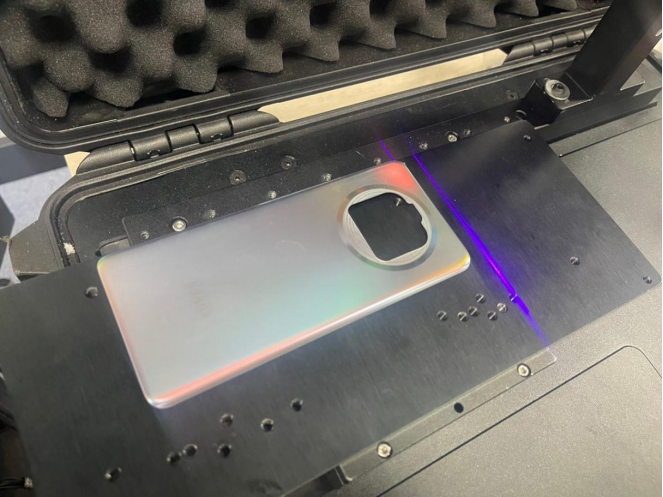

picture of real products

2.1 Requirements analysis

(1)Flatness test of the mobile phone back cover

(2)Cell phone back cover character detection

2.2 Product testing information

(1)Material: aluminum parts

(2)Color: silver white

2.3 Camera type selection

In view of the above detection requirements, the LVM2530-line laser 3D camera is also competent for this task. LVM2530 Mainly suitable for high-speed 3D detection of small parts; Can provide a 2,500 Hz full-frame acquisition rate, Number of physical contour points, 1,920 points, Depth map uniform spacing sampling maximum 4096 points; Acquisition rate of up to 56 KHz, With a Z-direction repeat accuracy accurate to 0.6 μ m, The Proximal End, 55.4 (FOV), Remote 90.5 (FOV) provides the best target visible, It is the ideal choice of high-speed online detection system; Less affected by the light, Ability to deal with certain light interference in the field detection environment; Support the output measurement data such as Modbus, Supports the communication with the PLC.

2.4 Detection environment and installation method

(1) Environmental Description: The product is placed on a linear servo platform, and the camera is horizontally fixed above the product.

(2)Installation method: the camera position is fixed to collect the image by horizontally moving the product.

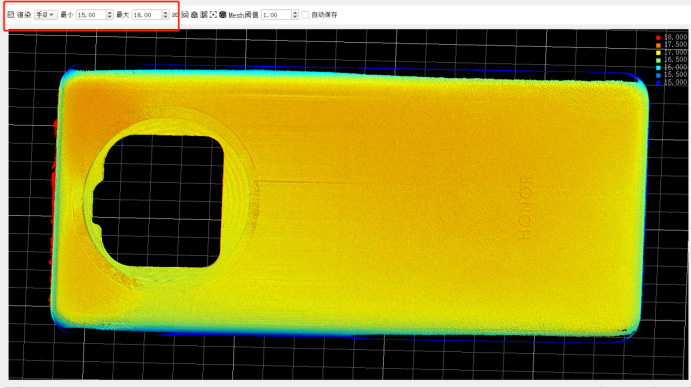

2.5 Drawing acquisition effect

Point cloud map

4. Test conclusion

YTV's LVM2530-wire laser 3D camera is sure to detect the flatness and characters of the back cover of the phone.

Testing value: save manual detection, replace coordinate sampling inspection, realize automatic detection, and improve product quality.

2023/07/07

2023/07/07