Betel nut point brine machine is a kind of equipment used for processing betel nut and lighting the brine. The traditional spot-halogen process requires manual operation, which is prone to the problem of unstable quality. After the introduction of 3D visual detection power, the automatic positioning and detection of betel nut cavity volume can be realized, so as to realize the automatic spot halogen process. This not only improves product consistency and quality stability, but also reduces manpower input and error rate, and improves production efficiency.

Today for you to introduce the application of technology line laser 3D camera in the food industry appearance detection application case!

1. Volume Detection of the betel nut cavity

2.1 Requirements analysis

(1)The volume of the areca nut cavity was examined

(2)Accuracy requirement: the volume measurement accuracy of betel nut cavity- - - ± 10%

Identification accuracy of path point coordinates- - - ± 1mm

(3) Beat requirements: 12S / 256 pieces

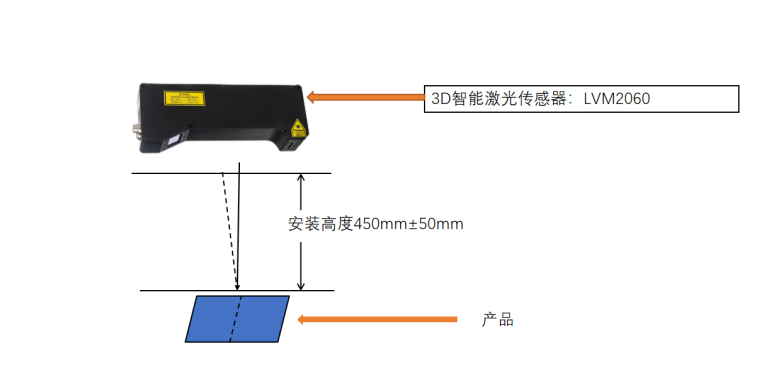

2.2 Camera type selection

For the above detection requirements, YTechnology's LVM2060-line laser 3D camera is capable of this task. LVM2060 Model comprehensive, meet the requirements of various high speed and mass detection applications; 340Hz full-frame acquisition rate, 2048 points of physical contour points, the depth map uniform spacing sampling up to 4096 points; accurate to 6 μ m Z direction repetition accuracy, the proximal 236.4 (FOV), the distal 543.0 (FOV) to provide the best target visible, is a cost-effective 3D intelligent sensor.

2.3 Detection environment and installation method

· The product is placed on a straight moving servo platform, the LVM 2060 camera degree is fixed above the sample, and the camera position is fixed to collect images by moving the sample horizontally

· Acquisition trigger mode: encoder trigger

· Communication: TCP / IP

· Installation height: 450mm ± 50mm

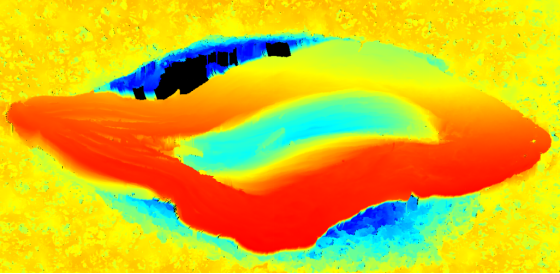

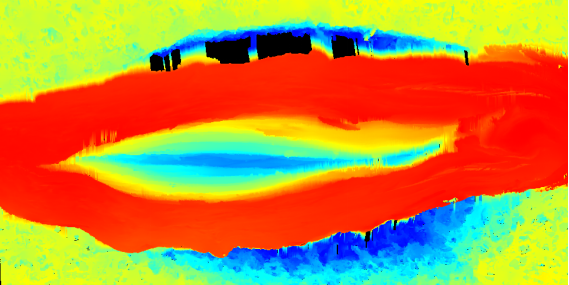

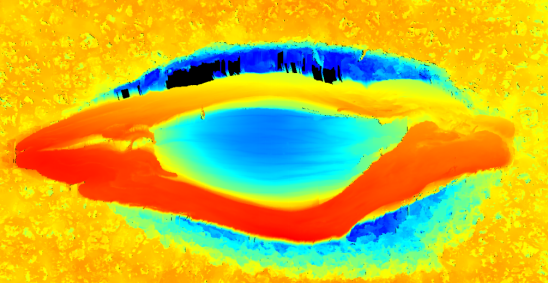

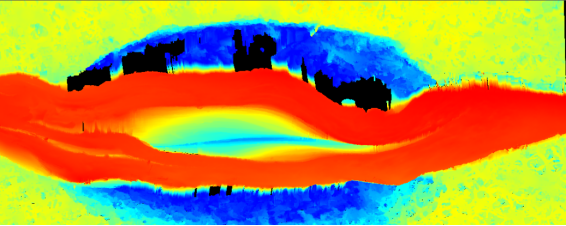

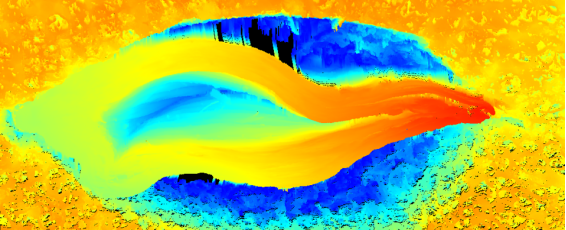

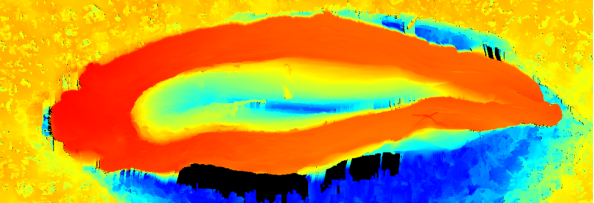

2.5 Drawing acquisition effect

2.5 Drawing acquisition effect

3. Test conclusion

The LVM 2060-line laser 3D camera of Next Vision Technology can obtain information such as the volume of the object cavity in a high precision and efficient way, which can meet customers' speed requirements of 12s / 256 pieces.

Detection value: By applying the 3D visual detection technology to the betel nut spot brine machine, automatic detection and rapid feedback can be realized, and the production quality and efficiency can be improved.

2023/08/08

2023/08/08