1. Background knowledge

With the continuous development of intelligent manufacturing technology, 3D visual technology has been widely used in the process of lithium battery manufacturing, the following visual visual detection technology application has covered lithium battery production process, through 3D visual inspection can improve the quality of lithium battery detection efficiency and accuracy, reduce labor cost, improve the intelligent level of automobile production line.

Today for you to introduce the application of technology LVM 2510 camera in lithium battery top sealing nail weld detection case!

1. Inspection of top cover seal nail weld

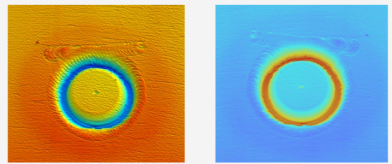

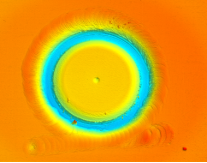

(picture of real products)

2.1 Requirements analysis

Material: aluminum parts

Color: silver white

Characteristics: the welding path is annular and concave under the inner ring is easy to form noise and blind area, and the sealing nail has strong reflection

Test requirements:

(1) Bulge: with the average height of weld as the benchmark, defect height> 0.2mm as NG

(2) No nail release or missing discharge is judged as NG, otherwise it is OK

(3) Warpped nail: the top face of the nail cap is 0.1mm high or low for NG, otherwise it is OK

2.2 Camera type selection

For the above detection requirements, YTechnology's LVM2510-line laser 3D camera is capable of this task. LVM2510 It is mainly suitable for high-speed 3D detection of small parts; it can provide 2500Hz full frame acquisition rate, physical contour points 1920 points, the depth map uniform spacing sampling up to 4096 points; the acquisition rate is up to 56 KHz, with Z direction repetition precision of 0.2 μ m., the proximal 13.3 (FOV), and the distal 16.2 (FOV provides the best target visible), which is a cost-effective 3D intelligent sensor.

2.3 Detection environment and installation method

· After the camera is fixed, the product is scanned and measured along the linear movement of the center;

· The rotating platform needs to have a stable encoder signal output;

2.4 Drawing acquisition effect

The sealing nail weld mark is clear, which can identify the splashing molten beads, warping nail, bulge and other defects

3. Test conclusion

The LVM2510-wire laser 3D camera of Yizhi Technology is sure to detect the welding joint detection requirements of the top cover seal nail, such as bulge, warping nail, no nail, etc.

Testing value: save manual detection, replace coordinate sampling inspection, realize automatic detection, and improve product quality.

About the next view

Founded in 2017, Yizhi Technology is a technology-based enterprise integrating the design, research and development, production, sales and service of industrial vision products. The company focuses on the underlying algorithm development and hardware realization of industrial vision products, and has a full set of independent intellectual property rights of software and hardware technology. To become the world's leading vision sensor company.

2023/09/14

2023/09/14