"Instance" sharing | 3D smart camera can assign precision PIN needle detection: open a new chapter of industrial automation

background knowledge

The PIN needle is a crucial element in the field of electronic engineering, which specifically refers to the metal pin used in the connector for electrical connection. Such metal pins usually act as electrical conduction and signal transmission in various electronic devices and components. Although the PIN needle is small, its function is extremely critical, and any manufacturing defect or damage may lead to circuit disconnection, signal error or failure.

The traditional manual detection methods are limited by their precision and consistency, and it is difficult to effectively carry out accurate quality inspection of a large number of small and dense PIN needles, which is prone to omission and misjudgment. And 3D visual detection technology to the PIN needle geometric size, shape, position and surface defects of contactless three-dimensional accurate detection, avoid the potential damage to PIN needle, greatly improve the quality of the detection and speed at the same time, effectively prevent the electronic product failure caused by manufacturing defects, further guarantee the quality of the product and long-term stability, for the electronic manufacturing industry has brought substantial technical innovation and production efficiency.

Camera selection

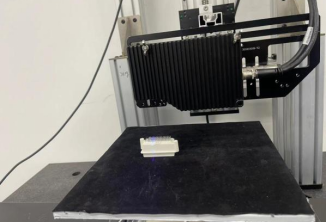

Today for you to introduce the application of technology LVM2320 line laser 3D camera in 3C industry detection case!

The LVM 2320-line laser 3D camera of Vision Technology is designed to meet the harsh production environment of the factory and meet the needs of various high-speed and mass-detection applications; it can provide 1000Hz full frame acquisition rate, physical contour 1920 points, depth map uniform spacing sampling maximum 4096 points; LVM2320 Z repetition accuracy accurate to 0.4 μ m, the proximal field range (FOV) is 28.1mm, and the distal vision range (FOV) provides the best target visible for 38.6mm, which is suitable for fast moving object detection scene.

Pin needle height and position degree detection

requirement analysis

· Material: plastic base + detected metal PIN needle

· Color: Silver PIN needle

Test requirements

· Precision requirements: repeatability data ± 0.02mm

Detection environment and installation method

· After the camera is fixed, the product is scanned and measured along the linear movement of the center;

· The test platform needs to have a stable encoder signal output;

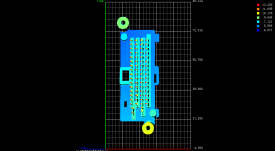

Drawing effect

Test conclusion

· The LVM 2320-line laser 3D camera of Vision Technology can accurately capture the geometry of the moving Pin needle on the high-speed conveyor belt, which can adapt to different heights of different parts, and realize effective detection to find out the broken needle and skew

· Detection value: it can provide scanning, measurement and control, and use independent algorithm to quickly verify real-time results; realize cost reduction and efficiency increase, and provide guarantee for enterprises and production

2024/03/13

2024/03/13